Showing 356 items matching "energy"

-

Federation University Historical Collection

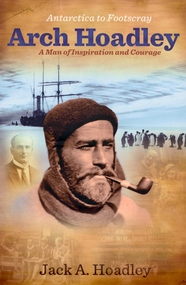

Federation University Historical CollectionBook, Jack A. Hoadley, Antarctica to Footscray: Arch Hoadley, 2010, 2010

Predominantly brown covered paperback of 460 pages featuring an image of Arch Hoadley in Antarctica on the cover.non-fictionballarat school of mines, antarctica, footscray technical school, baden powell, scouts, douglas mawson, arch hoadley -

Kew Historical Society Inc

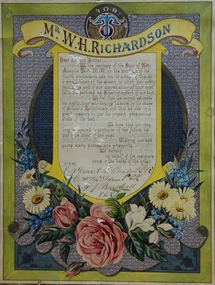

Kew Historical Society IncCertificate, Tribute to Mr W. H. Richardson from Members of the Star of Kew Juvenile Tent, 1887

Historical information - RECHABITES - The Star of Kew Tent, No. 260. This branch of the Independent Order of Rechabites was founded in September, 1882, when the following members were installed as the first officers by the district officers, viz. Chief Ruler, Bro. W. H. Bardwell; Deputy Ruler, Bro. C. Viney; Past Chief Ruler, Bro. J. V. Morgan; Treasurer, Bro. R. Eyre; Money Steward, Bro. A. Brown; Levite, Bro. W. H. Richardson; Guardian, Bro. J. Wathen; Secretary, Bro. T. J. Eaton. Bros. W. H. Bardwell, T. J. Eaton, and F. J. Legge were appointed as trustees. It is interesting to note that three of the foundation members, Messrs. Bardwell, Eaton, and Richardson, and still members of the tent. The first meetings were held in the Mission Hall, but for many years the meeting place of the tent has been the Kew Town Hall. The funds of the tent have gradually accumulated until at the last audit they amounted to £2,097. For many years past the interest on the funds has been more than sufficient to meet all claims for sick pay. The total membership is now 140. The following past secretaries have been mainly instrumental in placing the tent in its present position:-Bros. T. J. Eaton, W. H. Bardwell, C. B. Gray, and C. L. Churcher. The present officers are :- C.R., Bro. R. M. Jones; D.R., Bro. T. H. B. Williams; P.C.R., Bro. C. H. Green; Treasurer, Bro. W. J. Thornton; Secretary, Bro. F. C. W. Hurrell. Junior Branch. A junior branch was founded in 1883, and while its membership has fluctuated considerably according to the enthusiasm of the management, it has been the means of introducing many members to the senior tent. Its membership is now 41. Female Branch. Lily of Kew Tent, No. 20. This branch was formed in October, 1904, and has accomplished good work. Its membership is 38. Much of its success is due to the untiring energy of its secretary, Mrs. J Jaycock. Source: Barnard, FGA, Jubilee History of Kew, Victoria, 1910This document forms part of a large collection of material assembled by the Rogers family of Kew and donated by the family to the Kew Historical Society by Dorothy Rogers or by her sons. The items in the collection have social and spiritual significance and are also historically significant. Items such as this coloured lithograph have a degree of artistic and aesthetic significance as representative examples of the certificate designers art in the 19th Century. A certificate awarded to W. H. Richardson (the father of the historian Dorothy Rogers) by the ‘Juvenile Tent No.157 in appreciation of his role as ‘Superintendent’. The certificate notes that 1887 was the fourth anniversary of the Juvenile Tent. The Star of Kew Tent No. 260 had been formed in 1882 as a branch of the Independent Order of Rechabites. W. H. Richardson was a founding member.star of kew tent no.260, independent order of rechabites, william h richardson, rogers collection, testimonials -

Kew Historical Society Inc

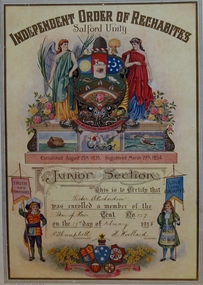

Kew Historical Society IncCertificate, Independent Order of Rechabites, Sister Richardson : Member of the Star of Kew Tent, 1915

RECHABITES. The Star of Kew Tent, No. 260. This branch of the Independent Order of Rechabites was founded in September, 1882, when the following members were installed as the first officers by the district officers, viz. Chief Ruler, Bro. W. H. Bardwell; Deputy Ruler, Bro. C. Viney; Past Chief Ruler, Bro. J. V. Morgan; Treasurer, Bro. R. Eyre; Money Steward, Bro. A. Brown; Levite, Bro. W. H. Richardson; Guardian, Bro. J. Wathen; Secretary, Bro. T. J. Eaton. Bros. W. H. Bardwell, T. J. Eaton, and F. J. Legge were appointed as trustees. It is interesting to note that three of the foundation members, Messrs. Bardwell, Eaton, and Richardson, and still members of the tent. The first meetings were held in the Mission Hall, but for many years the meeting place of the tent has been the Kew Town Hall. The funds of the tent have gradually accumulated until at the last audit they amounted to £2,097. For many years past the interest on the funds has been more than sufficient to meet all claims for sick pay. The total membership is now 140. The following past secretaries have been mainly instrumental in placing the tent in its present position:-Bros. T. J. Eaton, W. H. Bardwell, C. B. Gray, and C. L. Churcher. The present officers are :- C.R., Bro. R. M. Jones; D.R., Bro. T. H. B. Williams; P.C.R., Bro. C. H. Green; Treasurer, Bro. W. J. Thornton; Secretary, Bro. F. C. W. Hurrell. Junior Branch. A junior branch was founded in 1883, and while its membership has fluctuated considerably according to the enthusiasm of the management, it has been the means of introducing many members to the senior tent. Its membership is now 41. Female Branch. Lily of Kew Tent, No. 20. This branch was formed in October, 1904, and has accomplished good work. Its membership is 38. Much of its success is due to the untiring energy of its secretary, Mrs. J Jaycock. Source: FGA Barnard, Jubilee History of Kew, Victoria, 1910This document forms part of a large collection of material assembled by the Rogers family of Kew and donated by the family to the Kew Historical Society by Dorothy Rogers or by her sons. The items in the collection have social and spiritual significance and are also historically significant. Items such as this coloured lithograph have a degree of artistic and aesthetic significance as representative examples of the certificate designers art in the 19th Century.A colour lithograph, following a standard Rechabite design recording that Sister Richardson (later the historian Dorothy Rogers) joined the Junior Section of the Star of Kew Tent of the Independent Order of Rechabites on 17 February 1915. The certificate features biblical scenes and figures exhorting ‘Truth and Temperance’ and ‘Love and Purity’.independ, independent order of rechabites, dorothy (richardson) rogers, membership certificates, rogers collection, lily of kew tent, no. 20 -

Kew Historical Society Inc

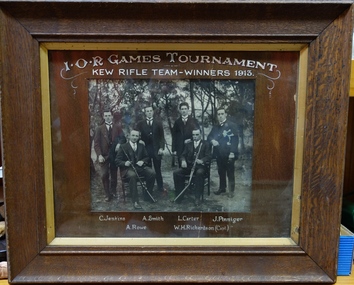

Kew Historical Society IncPhotograph, I.O.R Games Tournament: Kew Rifle Team - Winners, 1913

Extract fro FGA Barnard - Jubilee History of Kew 1910 RECHABITES.-The Star of Kew Tent, No. 260. This branch of the Independent Order of Rechabites was founded in September, 1882, when the following members were installed as the first officers by the district officers, viz. Chief Ruler, Bro. W. H. Bardwell; Deputy Ruler, Bro. C. Viney; Past Chief Ruler, Bro. J. V. Morgan; Treasurer, Bro. R. Eyre; Money Steward, Bro. A. Brown; Levite, Bro. W. H. Richardson; Guardian, Bro. J. Wathen; Secretary, Bro. T. J. Eaton. Bros. W. H. Bardwell, T. J. Eaton, and F. J. Legge were appointed as trustees. It is interesting to note that three of the foundation members, Messrs. Bardwell, Eaton, and Richardson, and still members of the tent. The first meetings were held in the Mission Hall, but for many years the meeting place of the tent has been the Kew Town Hall. The funds of the tent have gradually accumulated until at the last audit they amounted to £2,097. For many years past the interest on the funds has been more than sufficient to meet all claims for sick pay. The total membership is now 140. The following past secretaries have been mainly instrumental in placing the tent in its present position:-Bros. T. J. Eaton, W. H. Bardwell, C. B. Gray, and C. L. Churcher. The present officers are :- C.R., Bro. R. M. Jones; D.R., Bro. T. H. B. Williams; P.C.R., Bro. C. H. Green; Treasurer, Bro. W. J. Thornton; Secretary, Bro. F. C. W. Hurrell. Junior Branch. A junior branch was founded in 1883, and while its membership has fluctuated considerably according to the enthusiasm of the management, it has been the means of introducing many members to the senior tent. Its membership is now 41. Female Branch. Lily of Kew Tent, No. 20. This branch was formed in October, 1904, and has accomplished good work. Its membership is 38. Much of its success is due to the untiring energy of its secretary, Mrs. J Jaycock.Large framed photograph, of the Kew Rifle Club in 1913.I.O.R GAMES TOURNAMENT / KEW RIFLE TEAM WINNERS 1913. / C. Jenkins - A. Smith - L. Carter - J. Pinniger - A. Rowe - W.H. Richardson (Capt)"kew rechabites, w.h. richardson, kew rifle team -

Parks Victoria - Wilsons Promontory Lightstation

Parks Victoria - Wilsons Promontory LightstationAnvil

As quoted from Wikipedia, ‘An anvil is a block with a hard surface on which another object is, struck. The block is as massive as it is practical, because the higher the inertia of the anvil, the more efficiently it causes the energy of the striking tool to be transferred to the work piece’. The lightstation’s anvil is a red-painted iron block with a conical beak or horn at one end that was used for hammering curved pieces of metal. It would have stood on a heavy free-standing pedestal, such as a large tree stump, to allow complete access to the item being hammered. Some anvils display the manufacturer’s name in the metal on the side, but this is not the case here, and its age, although unknown appears to be quite old, perhaps c.1900. It appears to have had a lot of use, and although no record of this survives, it is presumed that a forge operated on site for hammering, cutting, shaping and repairing tools such as bolts, nails, hooks, chain segments, pulley blocks, hinges, crow bars, picks, chisels, horseshoes and harness hardware. A hames hook (which forms part of the collar worn by a draught horse) survives at the lightstation as do many other heavy metal tools and pieces of equipment. The anvil is an example of the necessary resourcefulness and self sufficiency practiced by lightkeepers working and living in a remotely located workplace and home, and many of the iron items in the collection may have been repaired or even made on its working surface. As a lightstation manager Chris Richter used the anvil to manufacture pulley blocks for sash windows, repair brass door hinges & sharpen cold chisels, crowbars and picks and other lightkeepers have used this anvil for many fabricating jobs such as manufacturing ducting for the generator room ventilation system."The lightship only came in every three months with supplies and there would have been repairs to do between visits from a blacksmith - who would have had to travel on the ship. Also, the ship was only anchored in the bay long enough to unload supplies and collect and deliver lightkeeping staff – probably not enough time to get much smithy work done – especially if the weather packed it in and the ship had to depart. Lightkeepers in our time had to be self sufficient, resourceful and innovative and I imagine that would have been the case in the past." It has second level contributory significance.Red painted blacksmith's anvil. -

Melton City Libraries

Melton City LibrariesPhotograph, Schutt and Barrie Pty Ltd Chaff Cutting Mills, Unknown

Mary nee Barrie Robinson (1907 –1999) writes c1980 about her father Charles Ernest Barrie of Darlingsford Melton (1871 – 1931) Extract copied from her handwritten story - My father was born in Ballarat in 1871. … commenced his working life with a team of bullocks and a chaffcutter in the St Arnaud district, a work the he became most success at and would continue in to the end of his life. He eventually became the owner of a chaff mill at Melton station with an access line to the railway. [1900] The Schutt & Barrie partnership Dad later became involved in a Chaff mill at West Footscray run by John Ralph Schutt who when he met Dad was a very sick man and had begged Dad to come into the business and help him. That began a very happy association, the business was put on its feet. An empty quarry across Geelong Road opposite the mill was purchased, the chaffcutters were set up in the quarry and that was the start of a very busy and prosperous period. A branch line was run into the mill. Dad spent some afternoons at the mill going by train, and spending some hours there at night, at the same time running the farm with full time help. Two full 8 horse teams were used to work the land, which meant early rising for the horses to be fed and harnessed ready for the men to commence the days work. Charlie Lowe and Murdock Davey were two of the men who worked for Dad in those years. The firm purchased a mill at Parwan and Dad spent a lot of time and energy getting it running to their satisfaction. Monday was the day he spent time there also round the district of Parwan and Balliang. He came to know many of the their names were well known in our household for many years. [1920] Later a flour mill was built beside the Chaff mill at West Footscray but it never thrived like the mill. The chaff mill had many loyal and good men employed there and there was never any trouble between men and management. Willie Walters and Miss Renyolds were some I remember, other names me, Joyce would be able to name them. [Sister of Mary born 1920] Schutt and Barrie Pty Ltd Chaff Cutting Mills Melton South sitelocal architecture, local identities, agriculture -

Eltham District Historical Society Inc

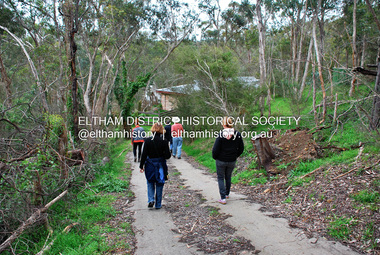

Eltham District Historical Society IncPhotograph - Digital Photograph, Jim Connor, River Bend House, 130 Laughing Waters Road, Eltham, 7 September 2013

Laughing Waters Walk, 7 Sep 2013 This Society excursion was a follow up to the Laughing Waters Story told to us by Jane Woollard at our Annual General Meeting in March 2013. It involved a walk commencing from the corner of Laughing Waters and Overbank Roads along Laughing Waters Road to its eastern end and returning partly over the same route - a total distance of about 2.5km. On the way we visited the two artist in residence properties, River Bend and Birrarung, to view the houses on them that are associated with Alistair Knox, Gordon Ford and others in the local mud brick and artistic community. We also able to walk around the derelict ruin which was once home to Gordon and Sue Ford, Boomerang House. An unexpected afternoon tea was offered to us by the artists in residence at Birrarung House and we had a brief opportunity to view inside the house. River Bend was designed and built by Alistair Knox for Rosemary and Bill Cuming in 1968. It sits in a deep cutting on a steep slope above the Yarra River and features floor to ceiling windows and glass doors set into mission brown timber frames and walls of reclaimed bricks in pinkish hue. Rosemary laid the brick paving around the house, a copy of the shell paving found in the ancient French town of Colmar, where the family had lived for a period. The kitchen was equipped with a 1960s stove as well as a cast iron wood stove reclaimed from Rosemary's sister's home in Armadale. Max and Tini Huygens, migrants from Holland, purchased the property in 1975 and named it Tilwinda from an Aboriginal word meaning 'hole in a rock'. In late 1981 Tini died after a short illness, but Max continued to live at Tilwinda until he moved to a retirement village in 2000 and the property was sold to Parks Victoria. Renamed River Bend, the property became part of the Laughing Waters Artist in Residency Program in 2008. Nillumbik Shire Council upgraded the property in 2012 with solar panels, a heat pump for hot water and double glazing to improve the comfort of the artists in residence and make the house more energy efficient. For a more in-depth description of the property and biographies of the various artists in residence commencing from 2008 to 2015, see Jane Woollard's book, "Laughing Waters Road; Art, Landscape & Memory in Eltham" published 2016.2013-09-07, activities, artists in residence, eltham district historical society, heritage excursion, jim connor collection, laughing waters road, river bend house -

Melton City Libraries

Melton City LibrariesDocument, 'Schutt and Barrie Flour Mill envelope, Unknown

SUMMARY - Schutt & Barrie Chaff Mills Partnership West Footscray, Parwan and Diggers Rest. Mary nee Barrie Robinson (1907 –1999) writes c1980 about her father Charles Ernest Barrie of Darlingsford Melton (1871 – 1931) Extract copied from her handwritten story - My father was born in Ballarat in 1871. … commenced his working life with a team of bullocks and a chaffcutter in the St Arnaud district, a work the he became most success at and would continue in to the end of his life. He eventually became the owner of a chaff mill at Melton station with an access line to the railway. [1900] The Schutt & Barrie partnership ….Dad later became involved in a Chaff mill at West Footscray run by John Ralph Schutt who when he met Dad was a very sick man and had begged Dad to come into the business and help him. That began a very happy association, the business was put on its feet. An empty quarry across Geelong Road opposite the mill was purchased, the chaffcutters were set up in the quarry and that was the start of a very busy and prosperous period. A branch line was run into the mill. Dad spent some afternoons at the mill going by train, and spending some hours there at night, at the same time running the farm with full time help. Two full 8 horse teams were used to work the land, which meant early rising for the horses to be fed and harnessed ready for the men to commence the days work. Charlie Lowe and Murdock Davey were two of the men who worked for Dad in those years. The firm purchased a mill at Parwan and Dad spent a lot of time and energy getting it running to their satisfaction. Monday was the day he spent time there also round the district of Parwan and Balliang. He came to know many of the their names were well known in our household for many years. [1920] Later a flour mill was built beside the Chaff mill at West Footscray but it never thrived like the mill. The chaff mill had many loyal and good men employed there and there was never any trouble between men and management. Willie Walters and Miss Renyolds were some I remember, other names me, Joyce would be able to name them. [Sister of Mary born 1920] Sample envelope from the businesslocal identities -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Folder, Marshall, Robert

Robert Marshall grew up on a small farm in Panton Hills in the 1950s and became an architect, designing in an Australian style, sometimes working with Alistair Knox. Marshall first stood for local council in 1974, having to overcome a childhood stutter by relaxation techniques. He was active in the formation of Nillumbik shire; after 20 years as councillor, he was elected president for 1978 and 1979. In February 1997, his adopted son Stewart Anthony Marshall died as the result of a drug mix-up. He lived in St Andrews and his business was in Hurstbridge. Contents Newspaper article: "Rob Marshall: fist of steel in a glove of green", The Valley Voice, 24 January 1979, describing Robert Marshall's childhood and his thoughts about house design and conservation. Newspaper article: "Councillor marshals energy for next round", Diamond Valley News, no date, Robert Marshall plans to stand again for council after the amalgamation of council, describing. his vision for the district citing Alistair Knox and Don Maling as pioneers. Newspaper article: "...and your new shire president", Diamond Valley News, March 1997, Former Eltham councillor Robert Marshall elected Nillumbik Shire president. Newspaper article: "Drug mix-up led to death: court told", unknown newspaper, 28 May 1997, Report of Coroners Court hearing into death of Stewart Anthony Marshall, Robert Marshall's son. Newspaper article: "Shire chief set to pay outstanding rate bill", Diamond Valley News, 30 July 1997, Robert Marshall had not paid rates in protest during government-appointed commissioners were in power but was paying off the debt. Newspaper article: "An architect for a better way of life", Diamond Valley News, 11 August 1981, Describing Robert Marshall's travels after qualifying as an architect, his early life and his philosophy on conservation. Newspaper article: "He presides over the city's last green belt. But was does Robert Marshall make the State Government see red?" The Age, 10 January 1998, Describing dispute between Nillumbik Shire president Robert Marshall and CEO Barry Rochford, and Rochford's termination package and Marshall's environmental campaigns including the old Eltham Shire Office site. Newspaper letter: "For good governance", letter from Robert Marshall, following his defeat at recent council election after 25 years in local government, comments on his actions as president and wishes new councillors well. Newspaper clippings, A4 photocopies, etcrobert marshall, panton hills victoria, alistair knox, stewart anthony marshall, ross ray qc, vauclause hospital, benny monheit, adam bernhaut, geoff pittaway, metropolitan ambulance service, ambulance service victoria, eltham gateway action group, barry rochford, eltham shire offices site, frank lynch, eltham chamber of commerce, barry miller, rob maclellan planning minister, green wedge, don maling -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, Between 1859-1941

TROVE : Argus (Melbourne, Vic. : 1848 - 1957), Monday 17 January 1859, page 7 TO the PHYSICIANS of AUSTRALIA -WOLFE'S SCHIEDAM AROMATIC SCHNAPPS, A superlative Tonic, Diuretic, Anti-Dyspepsic and invigorating Cordial. This medical diet-drink is manufactured soley by the proprietor at his distillery, in Schiedam, in Holland, expressly for medicinal purposes. It is the pure tincture of juniper, distilled from the best barley that can be selected in Europe at any cost. It is flavored and medicated, not by the common harsh berry, but by the choice botanical variety of the aromatic Italian juniper berry, whose more vinous extract is distilled and rectified with its sphirituous solvent, and thus it becomes a concentrated tincture of exquisite flavor and aroma, altogether transcendent in Its cordial and medicinal properties to any alcoholic stimulant now in use In the world. It has been submitted to all the first chemists and physicians in the United Slates, who endorse it over their own signatures as one of tho great essentials of the materia medica. It is now proscribed with great success In gravel, grout, rheumatism, obstruction of the bladder and kidneys, dyspepsia, whether acute or chronic, in general debility, sluggish circulation of the blood, inadequate assimilation of food, and exhausted energy, are acknowledged by the whole medical faculty and attested in their highest written authorities. Put up in quart and pint bottles, enveloped In yellow paper, with the proprietor's name on the bottle-, cork, and label. For sale by all the respectable druggists and merchants. UDOLPHO WOLFE WILKINSON BROTHERS and Co., sole agents for Australia. Depots at Melbourne and Sydney. TROVE : Farmer and Settler (Sydney, NSW : 1906 - 1955), Tuesday 30 March 1915, page 2 TRADING WITH UDOLPHO WOLFE. At the Sydney summons court on Wednesday morning, Laurence Edward Moss and Lawrence David Phillips were charged with having attempted to trade with the enemy by means of a letter addressed and posted to Udolpho Wolfe Company, Hamburg, Germany. There was a second information alleging that on or about December 7 last they attempted to trade with the enemy by means of a cable addressed and trans-mitted to Wolsey, New York. At the request of Mr. Campbell, K.C., who appeared for the defence, an adjournment to April 7 -was granted. Bail was allowed, each in £200, with a surety in £200. TROVE : Age (Melbourne, Vic. : 1854 - 1954), Wednesday 19 November 1941, page 4 WOLFE'S Aromatic SCHNAPPS Wolfe's Schnapps is now distilled in Australia from the original formula of Udolpho Wolfe. It remains, as before, a beverage of unique medicinal properties — Appetising, Refreshing, , Stimulating — as good for women as for men. -Wolfe's 'Schnapps for your health's sake FOR VICTORY-buy War Bonds Now . W.B.157.13 Olive green glass bottle for stopper seal, square in section, slightly tapering toward base, text embossed on three sides, circular ring embossed inside impressed circle on base.Side 1. : 'UDOLOPHO WOLF'S'. Side 2 : 'SCHIEDAM'. Side 3 : 'AROMATIC SCHNAPPS'. Base : an embossed ring inside a round impressed into the square base.schnapps, schiedam, gin, udolpho wolfe -

Federation University Art Collection

Federation University Art CollectionPainting, Norman Hofmaier, 'Promethius 1 from the Mallee Mysteries Series', by Norman Hofmaier

Norman Keith HOFMAIER (12.08.1951- ) Born Beulah, Wimmera, Victoria Norman Hofmaier was a scion of a well-known family, he completed his secondary education at Hopetoun High School and Ballarat College. Later he studied Visual Art at University of Ballarat, including painting, design and sculpture. Hofmaier’s childhood in Beulah was spent on the family property running beside the Yarriambiack Creek. Both he and his father had an intimate knowledge of the flora and fauna of the Mallee. The Wyperfeld National Park, home to the Big Desert, was a favourite place for Norman’s uncle who planted acres of native trees at the family property. Dr Di Bresciani explains: “The colours and vastness of the Mallee are represented in many works which reflect, variously, the relentless quiet and swirling energies found in the ‘dust storm might’ of the Mallee area. Most works may be described as abstract, lyrical abstract or abstract expressionist." From the 1970s until the 1990s he began an outpouring of work, using oil-based paints overlaid manually on large, specially-prepared boards using brushes, cloths, sponges, sprays or rollers. Petrol solvents were used to soften, blur and enhance shapes and edges. His work reflected his exploration of his inner state, sometimes flowing and placid, sometimes tempestuous. After a brief sojourn into city-life Norman returned to working in the country, until finally submitting to mental illness and permanent care in the mid 1990s. Norman Hofmaier's works are represented in major collections including that of the well- known artist Mitch Pearson ( an important influence and lifelong friend). The work 'Pastel of a Nude' was shown in a widely distributed magazine and two works owned by Mark Shannon were planned to be published as record covers in 1993. He won an award during the bicentennial recognising his skill as a Wimmera artist. From the 1970s until the 1990s he began an outpouring of work, using oil-based paints overlaid manually on large, specially-prepared boards using brushes, cloths, sponges, sprays or rollers. Petrol solvents were used to soften, blur and enhance shapes and edges. This work was purchased from the exhibition 'Norman Hofmaier: Mallee Mysteries' at the Lost Ones Gallery in Camp Street, Ballarat. The exhibition explored the legacy of Hofmaier’s work as well as raising money for the Ballarat Art Foundation. The Hofmaier family donated 16 works of the artist to be sold to raise funds for the foundation, to support emerging artists.Original painting in square format, featuring abstract swirls of blue, white, red, yellow and green.On back of work: 1. pools of diluted oil paint covering approximately 8 cm from each edge, 2. in right hand corner in permanent marker "N Hofmaier" 3. middle right hand side, torn exhibition label, with the words, "Belauh", "Local Art", "Prome", "Local Art", "$350", "Collect A", "oin" 4. Bottom right corner, two exhibition labels on card. Cards read: The flowing of movement before any known bodies are formed. Matter and gases bubble forming kaleidoscopic colours and shapes. Promethius 1 Oil based pigment with petrol on prepared board 1320 x 1210 mm On front of work, bottom right hand corner, in white lettering, N Hofmaier. Bottom right hand olive green frame damaged on front of work.painter, mallee, beluah, norman hofmaier, wimmera, abstract, alumni -

Melton City Libraries

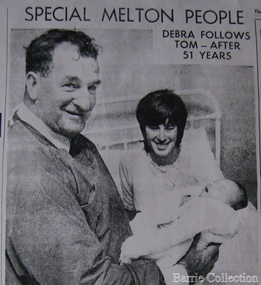

Melton City LibrariesNewspaper, Special Melton People, 1971

"Hannah ‘Grannie’ Wattsis one of Melton’s mostcelebrated and cherished pioneers. Born in Ireland in 1831, Hannah immigrated to Australia with her husband George Byrns in 1854. Moving to Melton, they built a wattle and daub hut home where they lived with their four children until George was tragically killed in 1860. Unusually for the time, Hannah purchased land in her own name in the Melton township in 1863. Later that same year she married William Watts and together they moved to Toolern Vale and built a bluestone and mud brick home. It is believed that while travelling to Australia, Hannah assisted the ship surgeon and demonstrated a natural aptitude for the tasks assigned to her. When she was living in Melton she assisted other women in an unofficial capacity as neighbourhood midwife, while also working on her farm and raising her six children. By 1887, however, her reputation as a midwife had grown to such an extent that she was able to establish her own practice. William Watts died in 1874, but Hannah remained in Toolern Vale for the next twenty years. In 1894, she moved into the Melton township and built Lynch Cottage on the corner of Yuille and Sherwin streets, near Toolern Vale Creek. There she assisted in the births of hundreds of Melton residents, as well as the laying out of the deceased. Meticulous in her record keeping, Hannah Watts recorded the details of a total of 442 births between the years 1886 and 1921. Lynch Cottage was officially registered as a private hospital in 1911 and Hannah was listed in the Victorian Register of Midwives in 1917. Hannah Watts died on 21 October 1921, a few months after she assisted with the delivery of her final baby, Thomas Watts Minns. She was 90 years old. Hannah was buried in Melton Cemetery and mourned by the Melton community. Her obituary in the Gisborne Gazette is a testament to how beloved she was by the people she served: ... while in the absence of medical aid residents looked to Grannie as their doctor, philosopher and friend. Hundreds, in fact we might say thousands of people held the deceased in veneration ... A woman of great energy and determination combined with superior intelligence, Grannie conquered difficulties that would have made many falter... Today Grannie Watts is remembered by her descendants and by many locals in the City of Melton. Created in 1985, Hannah Watts Park honours Grannie Watts’ pioneering work for the health and wellbeing of hundreds of Meltonians. Not only is the park a fitting tribute to the memory of an outstanding citizen, it also continues to provide today’s residents and visitors with a space to walk, relax, gather and celebrate in Melton" .Tom Minns holding Debra Wain, first hospital baby to be born In Melton since 1921. Article featured in the Herald. Mother Rhonda Wain is featured in the photo too. local identities, local significant events -

Melbourne Legacy

Melbourne LegacyDocument, Australian Imperial Force, 1918

A leaflet issued by General William Birdwood to the AIF troops just after the Armistice on 11 November 1918 to end the first world war. 'To the officers, Non-Commissioned Officers and Men of the Australian Imperial Force. It is now just four that we have been serving together, often through days of hardship and peril, and often through times of well-deserved success. During this time I hope and think we have come to know each other well and I trust we realised how rightly we have confidence in each other. No words of mine can possibly express all I feel for the magnificent work which has been done by the Australian soldier during these long four years. It is well known and recognised, not only throughout the British Empire, but throughout the world - and now we have peace in sight, and peace after a victory in which the Australian soldier has taken so large a share. Even then, with peace there are still difficult times before us. Faith in our recent foe cannot quickly be established, and it may be that some little time yet we shall be able to relax no precautions, until we are assured of the complete and honest fulfilment of our terms. Then will come the difficult time of demobilisation, and it is regarding this that I wish to make a personal appeal to every single member of the AIF in the full confidence that it will be met as every other appeal to face and tackle the strongest positions has ever been met by the Australian solider. Never has the name of Australia stood higher than it does now throughout the world, thanks to the bravery of her soldiers, and it sup to everyone one of us to see that this is maintained, and that no reproach can be cast on the Australian Flag owing to any behaviour of ours. The time of demobilisation will undoubtedly be difficult and irksome - I fully realise what great personal self-restraint will certainly be required - but if each individual of us makes up his mind to do his best during these times, realising the good name we bear, I feel confident that all will go well. I want you to remember that everything possible will be done to look after and help the troops during this period, while every energy will be strained to get men back to their homes as soon as this possibly can be done. You will have to realise, however. that there is a great shortage of shipping, and that there must be a considerable inevitable delay. Play the game, boys, during this time, as you have always done, and add still more to the deep debt of gratitude which will always be acknowledged to you by the Empire and remembered by me as your comrade and commander. In the field, 14 November 1918.' (Signed) 'W Birdwood'.A rare example of a notice to troops about the Armistice.A leaflet issued by General Birdwood to AIF troops to commemorate the end of World War 1.world war one, soldier -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - Albert Ernest Richardson, Peter Anderson's article 2020

Albert Richardson was born on 22nd. June, 1902 to George Albert Richardson and Catherine Agnes (nee Flynn). He married Mavis Irene Yarwood on 23rd. December, 1931. Albert Richardson's childhood activities in Duncan Street, Long Gully, were influenced strongly by the occupation of his father and grandfather, both of whom were engine drivers on the Bendigo field. Albert had his own model goldmine, complete with poppet head, baling tanks etc and was up and ready to start work with the sound of the 7 a.m. mine whistles. Albert spent a short time working as a motor mechanic and then took up0 welling insurance with T & G. However, his heart was with the mines and he worked daytimes with T. & G. and then took off to learn engine driving with night shift in one of the mines. He gained his engine drivers' ticket in 1938 and began work at the Nell Gwynne. His longest work time was at the North Nell but he also had shorter spells at other mines. His leter work years were spent at John Brown, from where he retired in 1968. Albert had a deep regard for the working man and worked for many years in the position of Secretary at the Trades Hall, Bendigo. (adapted from biography in BHS Collection, written by I. Hendry, 1972) The Bendigo Historical Society holds a wide range of Bendigo mining records researched and written by Mr. Albert Richardson. He was President of the Bendigo Branch of the Royal Historical Society of Victoria from 1969 to 1971.When he joined the Bendigo Branch in 1966 he began compiling a history of the Bendigo mines. He spent many long hours researching at the Bendigo Mines Department, summarising mine records. He gathered relevant mining material wherever it could be obtained. He devoted most of his spare time and energy to the Society, conducting tours of the goldfields, writing articles and presenting talks to various organisations. His first and foremost interest lay in Victoria Hill. He examined mining reports and early newspaper articles to document its history. He envisaged the once fabulously rich hill as becoming a tourist attraction and campaigned vigorously to achieve this. In 1971 his dream was realised, when, with the help of South Bendigo Rotary Club 'The Hill' was cleaned up and historical site4s sign-posted. In 1972 the Bendigo Trust produced a booklet on Victoria Hill. Albert Richardson is acknowledged as the person ' on whose work and writings the text of this booklet has been based' The park adjoining Victoria Hill was named the Albert Richardson Reserve in his honour. Four newspaper clippings on mining, focusing on Albert Richardson's life; his passion for mining history and more generally, the work of engine drivers on the Bendigo goldfield. Clippings taken from the 'Bendigo Weekly' 2016, dated September 29 'Learner Drivers' , October 7 'Becoming qualified', October 14 'Steam power in his veins' and November 11 ' Victoria Hill over the decades'. All articles written by James Lerk in a series titled 'Discover Bendigo'. albert richardson, engine driver, mining, bendigo, boiler, engine room, mining cage, albert richardson reserve, victoria hill, george ellis, south bendigo rotary club -

Bialik College

Bialik CollegeMixed media (Item) - 2008 Edge Multimedia Festival

Photographs from a multimedia festival held at Bialik College in 2008. As part of the Information Technology program, teacher Brendan Cohen, shared work from students throughout the week. Please contact [email protected] to request access to this record.Edge [indistinct] 2008 CT Week at Bialik College We had an explosive and wonderful ICT week with our Multimedia Festival, The Edge, at Bialik. Our media Teacher, Brendan Cohen, displays student work in Flash, Adobe Premiere assignments, and photography. Each year level is shown the program and each morning teachers view samples of the work during morning briefing. The wondrous thing was a 6in6 contest in photography. 6 photos from each group were submitted, all taken as originals. Special effects could be gathered from internet sources. For example, one student put fire in the lenses of the subjectís dark glasses. The 6 secrets were: Magic A different perspective Inside out Going green Melting It's in the eyes. The second contest was to create a DVD cover for a movie of your life. One boy took 6 closeups of his face and manipulated them beautifully. Then he took another photo and merged all of them. It was extraordinary and the outputs were stunning. The energy all week was high. The second part of our ICT Multimedia Festival was a contest where students could submit an image file. ìCreate a DVD cover of a movie of your life.î Here is the winning entry. I asked Mikey to change his name on the cover in order to protect his identity. This he did. 2000s, 2008, bialik college, technology, media, photography -

Tarnagulla History Archive

Tarnagulla History ArchiveSet of Maps (Mining & Local Area), various

David Gordon Collection. A set of mining documents, maps and plans: 1. Dunolly Deep Leads - showing location and names of deep lead gold deposits in region around Dunolly including at Tarnagulla and Newbridge. Geological Survey of Victoria, Department of Minerals and Energy. Bulletin No. 62, Map No. 4 Dunolly (770 x 485 mm). 2. Poseidon Lead (Facsimile) 3. Nick O Time Lead (Facsimile) 4. Happy Go Lucky Mine prospectus and plan (colour copy) 5. Jones Creek GM Co. (Raven & Gourlay's) Waanyarra - Prospectus (colour copy) 6. Poseidon Area Plan (colour copy) and Poseidon Area map (B&W copy). 7. Cross-section diagram of Spread Eagle Reef 8. New Birthday Gold Mine - area map (colour copy) and mine cross-section ( (colour copy). 9. Cross section of Poverty Reef, by Department of Mines (B&W copy, 2 parts on A2 paper) 10. Time-Lease Graph for Watts Reef, Specimen Reef, Stony Reef, Poverty Reef (second page in detail), created by Eric WIlkinson for Ref Mining NL, 1995 11. 1859 Plan of the Gold Workings & Township of Sandy Creek, Shewing the Mining Leases, Extended Claims & Machinery by R.J. McMillan, Mining Surveyor (B&W copy) 12. Longitundinal and Transverse Vertical Sections of Poverty Reef, Sandy Creek 1859, by R.J. McMillan, Mining Surveyor (B&W copy) 13. Tarnagulla Locality Plan (B&W copy) 14. Universal Grid Reference Map (Topographic) for Laanecoorie North (2 copies) 15. Universal Grid Reference Map (Topographic) for Inglewood South 16. Poverty Reef, Plan showing shafts and early tenements, created by Eric WIlkinson for Ref Mining NL, 1995 17. Locality Map of mining leases in Tarnagulla 18. Plan and Elevation of part of Poverty Reef, Sandy Creek, showing the claims and positions of the shaft. by R.J. McMillan, Mining Surveyor (Facsimile, composed of taped together components) 19.Plan and Elevation of part of Poverty Reef, Sandy Creek, showing the claims and positions of the shaft. by R.J. McMillan, Mining Surveyor (Facsimile, composed of taped together components) -

Federation University Historical Collection

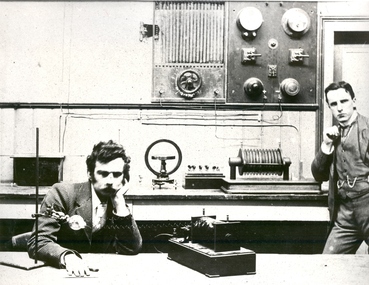

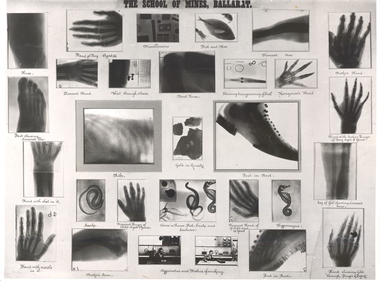

Federation University Historical CollectionPhotograph - Photograph - Black and White, X-Ray demonstration at the Ballarat School of Mines, 1896, 1896

X-Rays were first discovered on 8 November 1895. By 18 July 1896 staff members of the Ballarat School of Mines (SMB), were experimenting with the exciting new discovery. The history of x-rays began on 8 November 1895 at the University of Wurzburg in Bavaria. The discovery was officially announced on 25 December 1895. The first radiographs in Ballarat were taken at the School of Mines in July 1896 according to the Ballarat School of Mines (SMB) Annual Report. Frederick J. Martell, the Registrar of SMB arranged for the importation of tubes, while John M. Sutherland, an electrician, conducted most of the experiments giving 6 inch, 12 inch and 16 inch sparks respectively. In a short time brilliantly successful results were obtained, with some SMB Roentgen negatives taken at this time still in existence today. Samuel Ernest Figgis, H. R. W. Murphy, D. McDougall, and Frederick J. Martell carried out experiments at the SMB on Saturday evening 18 July 1896, producing 'perfect' negatives of a hand and wrist. A Roentgen Tube and an induction coil giving a two inch spark, the coil being sparked by the SMB's dynamo, were used to obtain these results. The Courier reported that 'the exposure of five minutes was ample' but concluded that 'the length of the exposure will be shortened as experiments proceed.' The Ballarat Courier reported on 20 July 1896 that: "Thanks to the energy of the staff of The School of Mines, Ballarat, and particularly to Messers F.J. Martell and D. McDougall, the assistance of Rontgen X-rays will soon be available, for the relief of suffering humanity, at this institution." Martell was an ardent amateur photographer, and Duncan McDougall's experience as an electrician has enabled the two gentlemen to carry their experiments on to a perfectly successful issue. At first these gentlemen, together with Professor Purdie and Mr W. Huey Steele, conducted a series of experiments by the aid of a Bonetti glass-plate induction machine which had been constructed by Mr McDougall. The results were very good, the various bones of the hand being distinctly visible. The following people were among those who witnessed the first X-ray experiments to be carried out in Ballarat. Andrew Anderson, President of the School of Mines, a large number of ladies and gentlemen, the medical profession Dr Edward Champion (1867-1929) Dr Gerald Eugene Cussen (1888-1943) Dr William Edward Davies (1868-1928) Dr Charles William Henry hardy (1861-1941) Dr Edward Kenneth Herring(1864-1922) Dr Joseph Lalor (1859-1907) Dr James Thomas Mitchell (1856-1945) Dr Edward Graham Ochiltree (1857-1896) Dr Robert Denham Pinnock (1849-1902) Dr Joseph Francis Usher (c1832-1909) Dr Grace Vale (nk-1933). The staff of SMB Professor Alfred Mica Smith Professor D. J. Dawbarn Mr. F. J. Martell. (http://guerin.ballarat.edu.au/aasp/is/library/collections/art_history/honour-roll/honourroll_X-Ray_pioneers.shtml)Two men, one seated, one standing standing in a room with early electrical equipment. They are conducting pioneer X-rays at the Ballarat School of Mines in 1896. Seated on the left is John Waters Sutherland.A bromide of this images states "Experimenting with X-rays, 1896"ballarat school of mines, x-ray, xray, john sutherland, sutherland, electricity, photography, foto, roentgen tube, medical -

Melton City Libraries

Melton City LibrariesNewspaper, Crosses lay out pledge to remember, 2015

"The outbreak of World War I in August 1914 had an immediate impact on communities across Australia, and it was no different in Melton. Young men began enlisting immediately, and Australia’s initial offer of 20,000 troops was soon exceeded by Victorian enlistments alone. Over the four years of the war, approximately 114,000 Victorians enlisted and around 91,000 servicemen and women were sent overseas. They came not just from Melbourne, but from all over the state; from farms, small towns and suburban areas. They included locals, newly arrived migrants and Indigenous people. The Australian home front was a hive of activity throughout the war, and the Melton community played its part. Following the announcement that Australia was joining the war with Great Britain and its allies on 5 August 1914, the Melton community lost no time in launching into action. A meeting ‘to assist the Red Cross fund’ was held in the Melton Mechanics’ Institute hall on 18 August – just days after the outbreak of the war. Collectors were appointed for each corner of the shire and individual donations were made. A Melton branch of the Australian Red Cross Society was formed in June 1915 and focused its energies on raising funds to purchase material that was used to make clothes for sick and wounded soldiers. A depot was established in Melton to collect clothing and other ‘comfort’ items for the soldiers – including reading material, tobacco, linen, canned foods and soap – and to coordinate the branch’s work and activities. Local cab driver Percival Stubbs volunteered to transport all the packages to the Melton railway station, until he enlisted and departed for the front in 1916. Such were the numbers of people getting involved that branches were also established in Toolern Vale and Rockbank. Regular community events were held to farewell soldiers who were leaving on active service and to welcome those who returned home. Gunner Robert (Bob) Wynne, whose uncle’s family ran the general store in Toolern Vale, was presented with a pair of field glasses (binoculars), a gold watch, inscribed locket and autographed letter by the Toolern Vale community before he set sail for the front in 1916. His mother noted that he ‘sailed away in good spirits with a smile till out of sight’. From June 1915 to June 1919, the Melton Red Cross branch donated 2,156 pairs of socks, 1,357 shirts, 425 kit bags, 251 pillowslips, 224 towels and 121 pairs of pajamas. Countless fundraising events were held, including jumble fairs, concerts and gift evenings. Local schools also encouraged students to contribute through fund-raising and making and collecting comforts for the soldiers. People across the country engaged in similar activities, but Victoria’s rural communities found unique ways of contributing. In Melton, people were encouraged to send rabbits and hares ‘in good condition’ to an exporter in Spencer Street, for export to Belgium ‘for the relief of those suffering". Special Anzac Memorial article featured in the Star Weeklylocal identities, war -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionAltona Collection Photography and Cataloguing - November 2024

In November 2024, a small group of cheerful volunteers from the Forests Commission Retired Personnel Association (FCRPA) toiled over nine days to dust-off, photograph and record nearly 300 artifacts in DEECA's Altona Museum. It followed a similar project at the FCRPA's Beechworth Museum in February 2024. The Altona project was generously supported by DEECA / FFMVic to engage professional photographer Mark Jesser from Wodonga whose boundless energy and good humour helped to create these amazing images. Special thanks go to the FFMVic Chief Fire Officer, Chris Hardman, as well as Andrew Stanios and Kat Jensen for making it happen. FFMVic crews and the ever-patient staff from Altona took a strong interest and also helped to shift some of the heavy items like pumps and the Bedford tanker which was very welcome. The Forests Commission and its successors continuously encouraged bushfire research and innovation. In 1946 a large parcel of industrial land was purchased at North Altona as a fire cache and workshop. The Altona workshop became a hotbed of new technological thingumajigs… a marvellous blend of Aladdin’s Cave of Wonders coupled with Wallace and Gromit’s madcap contraptions… an exhilarating place where lots of gizmos were invented and tested… mostly with astounding results... but nearly always with some head-scratching frustrations… and thankfully not too much explosive mayhem. In fact, a lot of Australia’s pioneering equipment development was led by staff from Altona, often in collaboration with other State forestry and fire authorities. The CSIRO also contributed significantly. The US Forest Service, the US Bureau of Land Management and US State agencies such as the California Department of Forestry and Fire (CalFire) as well as the Canadian Forest Service faced similar challenges and proved strong and willing partners in sharing knowledge, ideas, equipment and expertise over many decades. The collection at Altona started in the 1970s by fire equipment wizard Barry (Rocky) Marsden. As obsolete equipment was returned to the Fire Protection Workshop for auction, Rocky began the process of selecting some which would be interesting to retain and display. The items at Altona represent just a small sample of the amazing story of Victoria's forestry and bushfire heritage. The largest item was undoubtedly the Bedford tanker which took two days and nearly 1000 photos which were later stitched together with photoshop. The oldest item is probably the Ericsson wall telephone from 1904. There are also many unique items, but the CSIRO incendiary machine and ping-pong incendiary machine developed at Altona probably had the most significant impact on fire management in Australia. There are plenty of gaps in the collection, but some items are in regional DEECA offices. It’s hoped to merge the FCRPA's Beechworth collection to Altona one day and rename the site to honour Rocky Marsden. There may be some additions to the Altona museum over time, but space is limited. The museum is available to visit by appointment. Peter McHugh - January 2025 forests commission victoria (fcv) -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Colour Negative with a colour print, 1/03/1994 12:00:00 AM

Set of nine colour photographs of trams in Melbourne, c March/1994. Photographer details unknown. Date taken from date stamp on rear of photographs. Printed on Agfa paper. 35mm negatives filed. Two copies of each print except for 1440.7 to 1440.9 1440.1 - N241 - SW6 939 in St. Kilda Rd., inbound on route 15, with destination "Moreland" at the Arts centre. Has ABC 7.30 report ads on side. 1440.2 - N244 - A246, outbound in Victoria Parade on route 109 for Mont Albert. Taken after tram has passed the photographer. Done in "Energy Victoria" all over advertising livery. 1440.3 - N246 - SW6 877? or W6 977? running out of the Lansdowne St. shunt, inbound on route 12, "Sth Melbourne & St. Kilda Beach", run number A31, with driver changing points at crossover in Victoria Parade, East Melbourne. 1440.4 - N247 - SW6 874 and two other W's at Brunswick St. and Victoria Parade, East Melbourne. 874 on route 30, "City via Latrobe St". Photo taken after tram has passed photographer. Tram Has "Bank of Melbourne" advertising on end cab. 1440.5 - N248 - SW6 962 and SW5 840 at the intersection of Brunswick St and Victoria Parade. 962 out bound on route 12, 830 inbound on route 30. Both trams have "Bank of Melbourne" advertising on the end panels. 1440.6 - N249 - SW6 962 in bound on route 12 at same location on route 12. Has an A class in the background. 1440.7 - N243 - W6 995 outbound on Malvern - Burke Road, route 5 in St Kilda Rd at Arts Centre. Photo taken after tram has passed the photographer. Has an all over advertising livery, for "Australian Made" products. 1440.8 - N245 - A 266, in Victoria Parade, East Melbourne nearing Lansdowne St, inbound on route 109, showing destination of Port Melbourne. Has "Bertocchi is Better" advertising on driver's cab panel. 1440.9 - N242 - W7 1010 and W6 976, St Kilda Road, at the Arts Centre. W7 outbound on route 3, East Malvern Burke Road, and W6 inbound, showing route 5, but no destination. W7 appears to be recently painted. W6 has an all over advertising livery for "A Chorus Line".st kilda road, victoria parade, ptc, melbourne, tram 939, tram a 246, tram 874, tram 962, tram 840, tram 995, tram a 266, tram 1010, tram 967 -

Wodonga & District Historical Society Inc

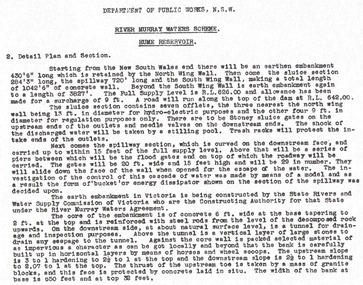

Wodonga & District Historical Society IncAlbum - Hume Reservoir Australia Album - Detail plan and explanation, Department of Public Works, N.S.W, 1927

This set of photos is from a leather bound album bearing the inscription "HUME RESERVOIR AUSTRALIA" plus 'The Rt. Hon. L. C. M. S. Amery, P. C., M .P.' all inscribed in gold. It was presented to The Rt. Hon. L. C. M. S. Amery, P. C., M. P, Secretary of State for Dominion Affairs on the occasion of his visit to the Hume Reservoir on 2nd November 1927. This album is of local and national significance as it documents the planning and development of the Hume Reservoir up to 1927. It was the largest water reservoir in the British Empire. The album records the pioneering engineering work that went into its construction.2. Detail Plan and Section. Starting from the New South Wales and there will be an earthen embankment 430 feet 6 inches long which is retained by the North Wing Wall. Then come the sluice section 284 feet 3 inches long, the spillway 720 feet long and the South Wing Wall, making a total length of 1,042 feet 6 inches of concrete wall. Beyond the South Wing Wall is earth embankment again to a length of 3,827 feet. The Full Supply Level is R.L.626.00 and allowance has been made for a surcharge of 9 feet. A road will run along the top of the dam at R.L.642.00. The sluice section contains seven offlets, the three nearest the north wing wall being 13 feet in diameter for hydro-electric purposes and the other four 9 feet in diameter for regulation purposes only. There are to be stony sluice gates on the upstream ends of the outlets and needle valves on the downstream ends. The shock of the discharged water will be taken by a stilling pool. Trash racks will protect the intake ends of the outlets. Next comes the spillway section, which is curved on the downstream face, and carried up to within 15 feet of the full supply level. Above that will be a series of piers between which will be the flood gates and on top of which the roadway will be carried. The gates will be 20 feet wide and 15 feet high and will be 29 in number. They will slide down the face of the wall when opened for the escape of the water. The investigation of the control of this cascade of water was made by means of a model and as a result the form of “bucket” or energy dissipater shown on the section of the spillway was decided upon. The earth embankment in Victoria is being constructed by the State Rivers and Water Supply Commission of Victoria who are the Constructing Authority for that State under the River Murray Waters Agreement. The core of the embankment is of concrete 6 feet wide at the base tapering to 2 feet at the top end and is reinforced with steel rods from the level of the decomposed rock upwards. On the downstream side, at about natural surface level, is a tunnel for drainage and inspection purposes. Above the tunnel is a vertical layer of large stones to drain any seepage to the tunnel. Against the core wall is packed selected material of as impervious a character as can be got locally and beyond that the bank is carefully built up in horizontal layers by means of horses and wheel scoops. The upstream slope is 3-to-1 hardening to 2½-to-1 at the top and the downstream slope is 2½-to-1 hardening to 2.07-to-1 at the top. The thrust of the upstream toe is taken by a mass of granite blocks, and this face is protected by concrete laid in situ. The width of the bank at base is 650 feet and at top 32 feet.hume reservoir australia, river murray waters scheme, hume weir diagrams, hume plan details -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBox, pill, 1930-1940 ref: Museum of Applied Arts and Sciences

As per another example in better condition displayed on shelf above Drawers 1+2 in Chemist ' Beechams Pills as sold by the proprietors St.Helens, Lancashire England. Beechams Pills Ltd. Melbourne VIC'. Earliest mention in Victorian Newspapers TROVE : Argus (Melbourne, Vic. : 1848 - 1957), Friday 19 December 1884, page 7 'A WONDERFUL MEDICINE BEECHAMS PILLS Are admitted by thousands to be worth above a guinea a box for bilious and nervous disorders such as wind and pain in tho stomach, sick headache, giddiness, fulness and swelling after meals dizziness and drowsiness, cold chills, flushings of heat, loss of appetite, shortness of breath costiveness, scurvy, blotches on the skin, disturbed sleep, frightful dreams, and all nervous and trembling sensations, &c The first dose will give relief in 20 minutes This is no fiction, for they have done it in thousands of cases. Every sufferer Is earnestly invited to try one box of these pills, and they will be acknowledged to be WORTH A GUINEA A BOX. For females of all ages these pills are invaluable as a few doses of them carry off all humours and bring about all that is required No female should be with-out them There is no medicine to be found to equal Beecham's Pills for removing any obstruction or Irregularity of the system. If taken according to the directions given with each box they will soon restore females of all ages to sound and robust health For a weak stomach, impaired digestion, and all disorders of the liver they act like "Magic, and a few doses will be found to work wonders upon the most important organs of the human machine They strengthen tho whole muscular system, restore the long lost complexion bring back the keen edge of appetite, and arouse into action with the rosebud of health, the whole physical energy of the human frame These are ' facts ' admitted by thousands embracing all classes of society, and one of the best guarantees to the nervous and debilitated Is Beechams Pills have the largest sale of any patent medicine in the world Full directions are given with each box Sold by all druggists and patent medicine dealers throughout the colonies'. Most recent article in Victorian newspapers : TROVE : Wodonga and Towong Sentinel (Vic. : 1885 - 1954), Friday 24 December 1954, page 1. 'MUM KNOWS BEST SHE KEEPS THE FAMILY FIT WITH BEECHAM'S PILLS SAFE because Beecham's Pills contain no harmful habit-forming drugs-they are a purely vegetable laxative. Pills balanced formula gives natural laxative action without harsh purgative effects banishes constipation. MOTHERS know how to keep growing children in their teens fit and happy-with Beecham' s Pill, the family laxative. TAKE Beecham's Pills WORTH A GUINEA A BOX'. Relevant local newspaper article reference : TROVE : Gippsland Times (Vic. : 1861 - 1954), Thursday 29 October 1942, page 1 'ln times like these old friends are best You will not have to go far before finding a friend who can tell you by personal experience how gentle and reliable Beecham's Pills are--and how effectively they banish head aches. digestive upsets and liverish ness. Purely vegetable....1/-....2/...per box Worth a guinea a box' Cylindrical wooden box with the remains of an orange, red and white printed label on top, containing small orb shaped pills.Label on lid : Beecham's pills...............Beecham's Pills Ltd., Melbourne, Vic.laxitive, pills -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaBooklet - Manual, Sailing directions for Port Phillip, in the colony of Victoria including the ports of Melbourne and Geelong, 1854

Captain Charles Ferguson was born in Scotland in 1813. He was the Master of the "Rajah" from 1838 to 1850 on voyages from England to Australia and vice versa. He became the First Chief Harbour Master for the port of Melbourne in 1852 after being the first Harbour Master and Water Police Officer in Geelong for 12 months. On the 5th of April 1841, the Rajah sailed with James Donovan M.D. as Surgeon Superintendent, and the Rajah sailed from Woolwich with 180 female convicts. The Rajah arrived on the 19th of July in Hobart, with 179 females (one died during the voyage) and 10 children. Miss Kezia Elizabeth Hayter was the matron on board. On page 28 of the "Sailing directions for Port Phillip, in the colony of Victoria including the ports of Melbourne and Geelong", a mention is made of the Mariner's Hospital and Floating Church soon to be established. There were discussions to built the hospital in Williamstown but instead the Government decided to build it in Melbourne. The Harbour Master and a commiittee decided to use the water police hulk, Emily, left unsold in 1856, to create a floating church: the Bethel was open in July 1857 with Reverend Kerr Johnston as Chaplain. Latrobe wrote a letter to Captain Cole in 1869, a few months after learning his death : "To Captain George Ward Cole † [from a draft in another’s hand] Clapham House, Lewes, Sussex, January 28th, 1869. My dear Captain Cole, Last mail will have taken out the sad intelligence of the death of our excellent old friend, Captain Ferguson. This will have been a terrible blow to his children and to his friends in the colony, who may have held reason to expect his early return to his home, with a not unreasonable prospect of ultimate restoration to health and activity. In the course of last October I went up to town with one of my children, mainly with the purpose of finding my way to Pinner, where he and Mrs. Ferguson were staying with an intimate friend. I found him in excellent health and spirits, and enjoying the prospect of a speeding resumption of the service to which he had devoted his best days, and upon the furtherance of which his entire energy was still directed. A week or two later Captain and Mrs. Ferguson went to Dover for change of air, and being still under the impression received from the advisers by whom they had been guided during their residence at a hydropathic establishment at Matlock, felt encouraged to plan almost immediate return to the colony by the Jerusalem early in December. However, certain misgivings in the mind of a medical gentleman, then in England, under whose care Captain Ferguson had at one time placed himself in Williamtown, led them to consider it judicious before departure to take the advice of some surgeon of eminence in London. Accordingly they came up to town at the close of November. The first London practitioners they consulted shook their heads, and advised consultation with Sir Wm. Ferguson. The result was that amputation, without loss of time, was pronounced necessary. The rest is soon told. He received the painful intelligence with calmness and full resignation to God's will, and underwent the operation at King's College Hospital with exemplary firmness and Courage on the 28th of November. Perfect success seemingly attended it, and there seemed, humanly speaking, to be every prospect of a prompt cure and early convalescence; everything seemed in his favour. A few days later, however, all was clouded by symptoms of hospital fever (pyoe æm ia). This resisted all control, and finally carried him off on the 27th of December, just one month after the operation. He had lived a Christian life, and his death was the peaceful and resigned death of a Christian. It was a melancholy satisfaction to me to be able to join a few friends in following his remains to their resting place in one of the outlying London cemeteries on the last day of the year. You know Mrs Ferguson well, and will be prepared to hear me say that her whole conduct and demeanour throughout this period of suspense and bitter trial has been worthy of her high character and steadfast principle. Come what will, and happen what may, I have the fullest conviction that neither the widow nor the children will be forsaken, however doubtful and clouded the future may appear, in consequence of the irreparable loss which, they have sustained. And now, dear Captain Cole, it is possible that you may already have heard all this from other sources, but I have dictated it to you under strong impulse, for I feel assured that there is no member of the community in which you live who will more sincerely deplore the loss of Captain Ferguson on private grounds; at the same time that there is no one who, from long acquaintance with his official character and services, will be in a better position to estimate their real value or the loss which the colony has sustained. The circumstances in which Captain Ferguson's family are left not only demands the utmost display of sympathy and interest on the part of friends, but may call for decided and prompt action; therefore I cannot rest satisfied without discharging what I consider my duty, and seeking to strengthen your hands as far as I may in bringing the character of his long services before the existing colonial authorities. Of his private career previous to his entering the service of the Colonial Government in 1851 nothing need be said. Captain Ferguson was appointed as the Harbour Master at Geelong in April, 1851 – a few months before the separation of the colony from New South Wales. He there did excellent service in a variety of ways calculated to advance the interests of the port, and to introduce www.latrobesociety.org.au 27 order, where, from circumstances, but little order had hitherto prevailed. His was the first appointment of this class in that locality. The separation of the colony from New South Wales took place in the month of July following. Shortly after, the late Captain Bunbury resigned the Harbour Mastership of Port Phillip. Captain Ferguson was at once (February, 1852) appointed to succeed him, and from that time performed all duties of Chief Harbour Master of the colony. The previous year (May 1851) the first gold discoveries in New South Wales had taken place, and in the month of August those of our colony followed. At the time of Captain Ferguson’s taking charge of the Port of Melbourne their influence had begun to be fully felt, and in no department more seriously than in that of the Harbour Master. This is no place for statistical details, but they must bear me out in reminding you of a few facts connected with our late friend’s career. At the time of separation that department comprised only 30 individuals of all ranks, and when he took charge the number was much reduced. There were at that time, according to the returns, no fewer than 54 vessels, registering 26,785 tons, in Hobson’s Bay alone. The crews on arrival numbered 1,235 men. Of this number only 463 remained on board, 500 having deserted, and the rest having been discharged by arrangement or pure necessity. For the first six months after Captain Ferguson’s assumption of office as Harbour Master the duties of Police Magistrate and Chief of the Water Police were superadded, and how much labour they involved may be surmised from the fact that from 1st of April to the 31st July, 1852, four months only, no less than 236 marine cases were brought before the bench at Williamstown - sometimes as many as 30 in a day. A year later (March 1853) the returns show that the number of vessels in the harbour in Hobson’s Bay alone were 91, tonnage 43,754; and passing on to the still later returns of May, 1853, two years after Captain Ferguson’s assumption of office, we find from the records that the number of ships in port had increased to 129; tonnage, 63,292; crew on board on arrival, 2872, and at the date of report, 1628; the amount of desertions at that time having, however, proportionally diminished, in consequence of the abatement of the gold fever, caused by the non-success attendant upon the labours of thousands at the goldfields. The above numbers take no account of the large number of vessels and amount of tonnage lying at the wharves at Melbourne or elsewhere. From these figures alone it may be judged what must have been a struggle in which the Chief Harbour Master was engaged from the very outset to secure order, and answer the innumerable calls on every branch of his department, at the same time that there was for many months an almost complete impossibility of securing subordinate agency, such as boatmen, pilots, and police, at any price. But I may bear witness to the untiring diligence, energy, and self-devotion with which Captain Ferguson grappled with the difficulties of his position, and the seemingly insurmountable obstacles which stood in his way. Ashore and afloat he was always ready, showing the same directness of purpose, intelligence, and forgetfulness of self. He shunned no responsibility, and turned his hand from no work, whether within or beyond the ordinary scope of his duty, which the hard necessity of the times forced the Government to bring under his notice. Already in 1852, when the overflowing of our gaol and stockade rendered the adoption of other methods of restraint absolutely necessary, and addition to the existing buildings could not be thought of, it was Captain Ferguson who first suggested the employment of hulks; and it was with his personal assistance and supervision, and under his unflagging energy, that the three first of these – the Success, the President, and the Sacramento – were purchased, fitted up, and made available for the purpose in view, and the rules and regulations for the employment and safety of the men afloat and ashore prescribed and carried out. He carried the same energy into every branch of his department, and his influence was soon apparent. His subordinates of every class became actuated by his spirit. As time moved on, the range of his duties, both ordinary and extraordinary, increased. In the formation of the quarantine station at the heads, in the management if not the erection of lighthouses, sailing directions, port and wharf regulations, buoys, signal stations, www.latrobesociety.org.au 28 steam dredging &c., he was the main and most active agent. The whole pilot establishment and regulations, men, and vessels, were under his charge; and when I left the colony in May, 1854, the entire range of ports outside Port Phillip Heads from Point Lonsdale to Portland, as well as that of Geelong had felt the influence of his intelligent supervision and care. The entire department of Chief Harbour Master, which I have numbered at the period of separation about thirty individuals, then numbered 230. The character of Captain Ferguson’s unbroken service during the fourteen years which have elapsed since I left the colony must be well known to the Government and the people he has served so long and so faithfully. I confine myself to recalling to mind those earlier, and what must have been the hardest and most difficult, period – none can know how difficult but those who were in that fierce struggle for the maintenance of order under so many disadvantages; and on this subject I have spoken advisedly and with reason, for I may truly say he worked under my own eye. I had sincere regard for the man, and just pride in the qualities of his heart, head, and hand. Whatever mistakes may have been made by the Government of the colony in those hard and difficult times (and I am quite ready to admit that there were many, especially if the past is to be judged by the light of the present), I never have hesitated in believing that, in appointing Captain Ferguson to the office he has so long filled, it was the right man in the right place. I shall be heartily rejoiced to find that the Government and inhabitants of the colony admit that this has been the case, and to learn that they have not forgotten the strong claims of one who has served them so long and so faithfully, and who, removed by God’s providence, so to say, in the maturity of his powers, has left a widow and young family behind him. I have done, I leave you to make use of this communication, or any portion of it, which you may think judicious and called for. There may be among Ferguson’s friends those who may not be sorry to be reminded of facts. By-the-bye, I may mention as a proof how completely Captain Ferguson’s mind was engrossed by devotion to his public duty, that while in Dover, only ten days before the operation, he took an opportunity to drag himself up into the lantern of the S. Foreland Lighthouse, and made a most careful scrutiny of the whole apparatus and arrangement, with a view of the adoption of any hint for the perfection of those under his charge in the colony. And now, goodbye. I trust this will find you in good health, and in comparative vigour. Believe me ever, dear Captain Cole, Yours very truly, C. J. La Trobe"The attempt for a floating church was made as early as 1853 following similar examples in London like the Seamen's Hospital. Captain Ferguson was instrumental in the foundation of the Bethel Church.Digital copies of the 37 pages ; 22 cm.1854, hobsons bay, geelong, melbourne, williamstown, sandridge, mariner's hospital, floating church, seamen's hospital, captain charles ferguson (1813-1868), kezia elizabeth hayter (1818-1885), rajah quilt, prison hulks, water police, harbour master, harbor master, gaols -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Original x-rays, X-rays from pioneering Ballarat Demonstrations, 1896, 1896

X-Rays were first discovered on 08 November 1895. By 18 July 1896 staff members of the Ballarat School of Mines (SMB), were experimenting with the exciting new discovery. The history of x-rays began on 08 November 1895 at the University of Wurzburg in Bavaria. The discovery was officially announced on 25 December 1895. The first radiographs in Ballarat were taken at the School of Mines in July 1896 according to the Ballarat School of Mines (SMB) Annual Report. Frederick J. Martell, the Registrar of SMB arranged for the importation of tubes, while John M. Sutherland, an electrician, conducted most of the experiments giving 6 inch, 12 inch and 16 inch sparks respectively. In a short time brilliantly successful results were obtained, with some SMB Roentgen negatives taken at this time still in existence today. Samuel Ernest Figgis, H. R. W. Murphy, D. McDougall, and Frederick J. Martell carried out experiments at the SMB on Saturday evening 18 July 1896, producing 'perfect' negatives of a hand and wrist. A Roentgen Tube and an induction coil giving a two inch spark, the coil being sparked by the SMB's dynamo, were used to obtain these results. The Courier reported that 'the exposure of five minutes was ample' but concluded that 'the length of the exposure will be shortened as experiments proceed.' The Ballarat Courier reported on 20 July 1896 that: "Thanks to the energy of the staff of The School of Mines, Ballarat, and particularly to Messers F.J. Martell and D. McDougall, the assistance of Rontgen X-rays will soon be available, for the relief of suffering humanity, at this institution." Martell was an ardent amateur photographer, and Duncan McDougall's experience as an electrician has enabled the two gentlemen to carry their experiments on to a perfectly successful issue. At first these gentlemen, together with Professor Purdie and Mr W. Huey Steele, conducted a series of experiments by the aid of a Bonetti glass-plate induction machine which had been constructed by Mr McDougall. The results were very good, the various bones of the hand being distinctly visible. The following people were among those who witnessed the first X-ray experiments to be carried out in Ballarat. Andrew Anderson, President of the School of Mines, a large number of ladies and gentlemen, the medical profession Dr Edward Champion (1867-1929) Dr Gerald Eugene Cussen (1888-1943) Dr William Edward Davies (1868-1928) Dr Charles William Henry hardy (1861-1941) Dr Edward Kenneth Herring(1864-1922) Dr Joseph Lalor (1859-1907) Dr James Thomas Mitchell (1856-1945) Dr Edward Graham Ochiltree (1857-1896) Dr Robert Denham Pinnock (1849-1902) Dr Joseph Francis Usher (c1832-1909) Dr Grace Vale (nk-1933). The staff of SMB Professor Alfred Mica Smith Professor D. J. Dawbarn Mr. F. J. Martell. (http://guerin.ballarat.edu.au/aasp/is/library/collections/art_history/honour-roll/honourroll_X-Ray_pioneers.shtml) "Seven patients of the doctors who were present were treated. In each case the patient was suffering from the effects of an old wound or some other injury to other a hand or foot. One patient, a boy had a finger broken some years earlier and when xray plate of the injury was developed it indicated plainly the fracture on one of the joints of the third finger. In another case a woman had a foot had a foot X-rayed and the photograph revealed the seat of an earlier imjury to it. Likewise an injury to the bones of a hand of an elderly man was revealed by an x-ray photograph. Every X-ray photograph that evening showed the importance of this new development in electrical science and the doctors present agreed the "the results of the experiments on their patients, by showing the exact seat of the injury and its present condittion, would materially assist them iin supporting cures." (Warren Perry, The Ballarat School of Mines and Industries Ballarat, p 146.)A number of photographic xrays as taken by the Ballarat School of Mines in 1896. The xrays include bones, hands, feet, shoes and more. ballarat school of mines, scientific equipment, x-ray, xray, photography, foto, roentgen tube -

Uniting Church Archives - Synod of Victoria

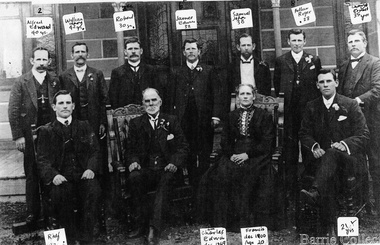

Uniting Church Archives - Synod of VictoriaPhotograph, C. 1870s