Showing 252 items

matching third years

-

Federation University Historical Collection

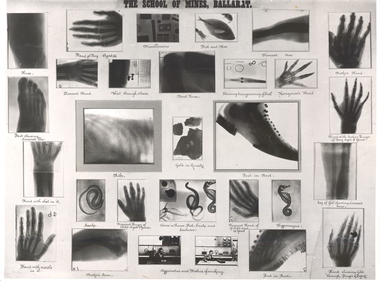

Federation University Historical CollectionPhotograph - Original x-rays, X-rays from pioneering Ballarat Demonstrations, 1896, 1896

X-Rays were first discovered on 08 November 1895. By 18 July 1896 staff members of the Ballarat School of Mines (SMB), were experimenting with the exciting new discovery. The history of x-rays began on 08 November 1895 at the University of Wurzburg in Bavaria. The discovery was officially announced on 25 December 1895. The first radiographs in Ballarat were taken at the School of Mines in July 1896 according to the Ballarat School of Mines (SMB) Annual Report. Frederick J. Martell, the Registrar of SMB arranged for the importation of tubes, while John M. Sutherland, an electrician, conducted most of the experiments giving 6 inch, 12 inch and 16 inch sparks respectively. In a short time brilliantly successful results were obtained, with some SMB Roentgen negatives taken at this time still in existence today. Samuel Ernest Figgis, H. R. W. Murphy, D. McDougall, and Frederick J. Martell carried out experiments at the SMB on Saturday evening 18 July 1896, producing 'perfect' negatives of a hand and wrist. A Roentgen Tube and an induction coil giving a two inch spark, the coil being sparked by the SMB's dynamo, were used to obtain these results. The Courier reported that 'the exposure of five minutes was ample' but concluded that 'the length of the exposure will be shortened as experiments proceed.' The Ballarat Courier reported on 20 July 1896 that: "Thanks to the energy of the staff of The School of Mines, Ballarat, and particularly to Messers F.J. Martell and D. McDougall, the assistance of Rontgen X-rays will soon be available, for the relief of suffering humanity, at this institution." Martell was an ardent amateur photographer, and Duncan McDougall's experience as an electrician has enabled the two gentlemen to carry their experiments on to a perfectly successful issue. At first these gentlemen, together with Professor Purdie and Mr W. Huey Steele, conducted a series of experiments by the aid of a Bonetti glass-plate induction machine which had been constructed by Mr McDougall. The results were very good, the various bones of the hand being distinctly visible. The following people were among those who witnessed the first X-ray experiments to be carried out in Ballarat. Andrew Anderson, President of the School of Mines, a large number of ladies and gentlemen, the medical profession Dr Edward Champion (1867-1929) Dr Gerald Eugene Cussen (1888-1943) Dr William Edward Davies (1868-1928) Dr Charles William Henry hardy (1861-1941) Dr Edward Kenneth Herring(1864-1922) Dr Joseph Lalor (1859-1907) Dr James Thomas Mitchell (1856-1945) Dr Edward Graham Ochiltree (1857-1896) Dr Robert Denham Pinnock (1849-1902) Dr Joseph Francis Usher (c1832-1909) Dr Grace Vale (nk-1933). The staff of SMB Professor Alfred Mica Smith Professor D. J. Dawbarn Mr. F. J. Martell. (http://guerin.ballarat.edu.au/aasp/is/library/collections/art_history/honour-roll/honourroll_X-Ray_pioneers.shtml) "Seven patients of the doctors who were present were treated. In each case the patient was suffering from the effects of an old wound or some other injury to other a hand or foot. One patient, a boy had a finger broken some years earlier and when xray plate of the injury was developed it indicated plainly the fracture on one of the joints of the third finger. In another case a woman had a foot had a foot X-rayed and the photograph revealed the seat of an earlier imjury to it. Likewise an injury to the bones of a hand of an elderly man was revealed by an x-ray photograph. Every X-ray photograph that evening showed the importance of this new development in electrical science and the doctors present agreed the "the results of the experiments on their patients, by showing the exact seat of the injury and its present condittion, would materially assist them iin supporting cures." (Warren Perry, The Ballarat School of Mines and Industries Ballarat, p 146.)A number of photographic xrays as taken by the Ballarat School of Mines in 1896. The xrays include bones, hands, feet, shoes and more. ballarat school of mines, scientific equipment, x-ray, xray, photography, foto, roentgen tube -

Federation University Historical Collection

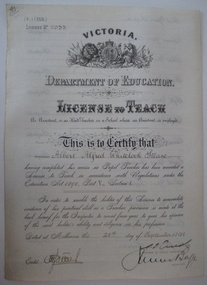

Federation University Historical CollectionCertificate, Education Department Victoria, License to Teach made out to Albert Steane, 25/09/1899

Born at Sandhurst, Victoria Albert Steane attended the Gravel Hill State School until the fourth class, then transferred to the Central School 1976 where he gained the Merit Certificate. The monitor system of teacher training had been introduced and he passed fourth, third, second and first class pupil teacher. At about 16 years of age he was appointed a teacher monitor at 12 pounds per annum. Albert Steane was awarded the Teachers' Certificate of Competency in 1897. He was the first headmaster of the Ballarat Technical School (1913), and opened the Sloyd (woodwork) Centre in 1902 at the Ballarat East Art School (later known as the Ballarat East Free Library). of Mines and Industries Ballarat (SMB). Steane is known for the teaching of Sloyd or woodwork, which was an important point in his career, and for his love of gymnastics. He was made a life member of the Ballarat Y.M.C.A. in 1968 aged 91 years. The teaching of woodwork in Victoria began in 1901 and Steane was chosen, among 18 others for the inaugural training course at Queensberry State School in Melbourne. Steane died, aged 93 years, on 13 July 1970, at Sydney, leaving his widow Grace Elliott Steane and children Eric and Violet. (See http://guerin.ballarat.edu.au/curator/honour-roll/honourroll_steane.shtml)Victorian Education Department License to Teach Certificate printed and handwriiten on to parchment like paper, made out to Albert Alfred Whitelock Steane. License No. .education, teaching, albert steane, aaw steane -

Federation University Historical Collection

Federation University Historical CollectionCalculator, Burroughs, Calculator (Adding Machine), c1935

The "Burroughs Calculator" was a non-printing key-driven machine introduced in 1912 in response to the success of the Felt & Tarrant "Comptometer". The first Burroughs key-driven machine was very similar to the Comptometer in its external appearance, but was quite different in its internal mechanism, with the register and carry mechanism based on a complex system of planetary gears. It was only about two-thirds of the weight of the Felt & Tarrant machine, and had none of the safety features. In particular, there was no protection against incomplete keystrokes in either direction. The register would simply advance in proportion to the depth of stroke, with no indication of error. However, the price was also about two-thirds of the Comptometer, which made it quite a popular (if dangerous) machine. (http://home.vicnet.net.au/~wolff/calculators/Burroughs/Burroughs.htm) The Burroughs Portable Adding Machine introduced in 1925 became the basic design for the adding machine for many years, until the ten key adder was introduced and started to replace it gradually. The key-driven type machine did not print, and while it was often used as an adding machine, it developed into a special purpose machine in later years. The machine was very fast . The efficient operation of these machines required an experienced operator who often received a high salary. The machine was produced over a very long period because of its unique capabilities and was often used to verify product delivery lists from delivery routes. Later models of the machine, called a duplex design, could hold a running total in a second set of dial wheels while the primary wheels continued to add and subtotal amounts that could be transferred at any time to the running total. A side note, Burroughs copied the Felt design for its first models and was sued for patent infringement by Felt and Tarrant who prevailed in the suit. As a result, Burroughs totally redesigned their machine and went on to compete with the Felt machine for decades. Info from (http://www.burroughsinfo.com/group_d.htm) Black metal low keyboard manual adding machine. The key-driven type machine did not print, and was exceedingly fast and experienced operators could easily outrun an operator on a full keyboard or 10-key adding machine. The adding machine has a brown leather carry case.calculator -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Scrimshaw, Hero 1870, Late 20th Century

Scrimshaw is regarded as early folk art and is associated primarily with whaling that was opened up in the Pacific at the end of the eighteenth century by sailors mainly from American, English and French vessels. As a result, some of the best scrimshaw from Pacific whales can be found in collections in these countries. Even though sailors must have had plenty of spare time between periods of whaling scrimshaw on whale teeth seems a rarity before the 1830s. One reason may have been the high price paid for whale teeth ivory in this period making scrimshaw on teeth popular only after the market was saturated and the price dropped. The earliest identified engraver of whale teeth is the English whaling master Captain J. S. King who was active between 1817 and 1823. There have been six ships called the Hero in the Royal Navy and this ship was the fourth named Hero, it was a screw-propelled 91-gun and second-rate. In the rating system of the British Royal Navy, this term is used to categorise sailing warships, a second-rate was a ship of the line which by the start of the 18th century mounted 90 to 98 guns on three gun decks. Earlier 17th-century second rates had fewer guns and were originally two-deckers or had only partially armed third gun decks. The Hero was launched in 1858 and sold in 1971. On July 1860 the Prince of Wales embarked onboard HMS Hero, Albert Edward Prince of Wales, was the eldest son of Queen Victoria, and the future King Edward VII, at the time he was then nineteen years of age, and on route to Newfoundland, Canada and the United States on his first state tour. He was the first member of the British royal family to visit North America. In 1860 the Queen had intended to pay a visit to Canada however stress prevented her from travelling. The then Prime Minister Lord Palmerston suggested that “Bertie” the prince of Wales could represent the Queen and on July 10th 1860, Bertie boarded HMS Hero for a tour of Canada and the USA. On July 23rd the ship arrived at Terranova. By the second week of August, the HMS Hero had sailed up the St. Lawrence River and anchored at Quebec. The Prince was successful with Canadian society visiting Quebec and Montreal during his stay. He went on to visit the United States following an invitation by President James Buchanan. His American journey was regarded as a great success. President Buchanan wrote to Queen Victoria: "He “Bertie” has faced a very difficult task for a person his age and his behaviour in all this has been that of his age and position. He has shown himself honourable, Frank and affable and he won the respect of the sensible and wise people". The scrimshaw is believed to be a modern reproduction of a typical scrimshaw scene and engraved very crudely onto a synthetic substance. Scrimshaw art carved into non-natural material in the shape of a whale tooth. The line artwork images of a three-masted, fully rigged ship and an anchor are coloured black. Inscription is engraved into tooth.Engraved "Hero 1870"warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scrimshaw, plastic, resin, replica, prince of wales, british navy vessel, whaling, hms hero, reproduction, carving, engraving -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Christening Gown, Sarah Lees, c. 1860's

In the words of the donor, Betty Stone, "This gown was originally made by my great grandmother Sarah Ellis (nee Chamberlain) Lees of Wangoom, Warrnambool. Later, the gown was altered by her daughter Ann (nee Lees) Dale who also used it for the christenings of her five children in the 1890's, and later still, for some of her grandchildren. Sarah Ellis Chamberlain, born in Thriplow, Cambridgeshire, England on 31 July 1844, sixth child of Joshua and Susan Chamberlain, was ten years old when she arrived in Australia with her parents and siblings in January 1855. Ten years later, in 1864, Sarah Chamberlain married Lees Lees, a skilled stonemason who had migrated from Saddleworth, Yorkshire. Lees Lees purchased land in McGregors Road, Wangoom, Warrnambool where he operated a successful stonemasonry, contracting business until his death in 1912. The Lees farm, which eventually consisted of about fifty acres, was situated adjacent to both the Chamberlain and Dale farms. Sarah Lees was a meticulous homemaker who also fashioned and sewed clothes for her seven children. A photograph of the eldest child, Anne, taken in 1868, depicts her wearing a dress and pantaloons sewn by her mother. Sarah also crocheted lace curtains for her home in addition to large tablecloths and other articles. According to family legend, the skirt of this christening gown was part of the original gown hand-sewn by Sarah (nee Chamberlain) Lees which was used for the christening of her children. The gown was later passed on to her daughter Anne (nee Lees) Dale who, also an expert needlewoman, replaced the bodice and used it for the christening of her five children born between the years 1890 and 1899. Still, later, at least two children of the third generation (Sarah Lees' great-grandchildren) also wore this gown when christened at Christ Church Warrnambool. Sarah (nee Chamberlain) Lees died in 1932, aged 87 years, at her daughter Anne Dale's home in Latrigg. Anne (nee Lees) Dale died in 1948 aged 83 years, at her home in Latrigg." (Note: For additional information please refer to Betty Stone’s book “Pioneers and Places - A History of three Warrnambool Pioneering Families” ie. Chamberlain, Dale and Lees Families)This item is associated with the families of Chamberlain, Dale and Lees. These families are listed in the "Pioneers' Register" for Warrnambool Township and Shire, 1835-1900, published by A.I.G.S. Warrnambool Branch. The item is a fine example of late-19th-century needlework and handmade domestic items.Christening gown made by Sarah Ellis. White with unusual Broderie Anglaise yoke. The long-sleeved garment has a gathered waist and a long skirt. The front centre of the skirt has a floral Broderie Anglaise and cut work panel insert.Circa 1860's. From the 'Chamberlain Dale Lees Collection’, donated by Betty Stoneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, chamberlain, dale, lees, stone, betty stone, warrnambool pioneers, sarah ellis, hand sewn, christening gown, baby wear, clothing, 19th century -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Black and white printed card, Ballarat Old Boys' Association presentation to Albert W.Steane, 1942, 1942

Albert Steane was born at Sandhurst (now known as Bendigo) in 1877. He attended the Gravel Hill State School until the fourth class, then transferred to the Central School 1876 where he gained the Merit Certificate. The monitor system of teacher training had been introduced and he passed fourth, third, second and first class pupil teacher. At about 16 years of age he was appointed a teacher monitor at 12 pounds per annum. Albert Steane was awarded the Teachers' Certificate of Competency in 1897. The teaching of woodwork in Victoria began in 1901 and Steane was chosen, among 18 others for the inaugural training course at Queensberry State School in Melbourne. Steane was known for the teaching of Sloyd or woodwork, which was an important point in his career. He opened the Sloyd (woodwork) Centre in 1902 at the Ballarat East Art School (later known as the Ballarat East Free Library) at the School of Mines and Industries Ballarat (SMB). In 1913 Albert Steane, the young head of the East Ballarat Sloyd Centre, was appointed to establish a junior technical school in Ballarat becoming the first headmaster of the Ballarat Junior Technical School. Steane's lifelong interest in gymnastics brought him as much fame as his reputation as a headmaster. He organised the Education Department's gymnastics display at Bendigo's Golden Jubilee Exhibition in 1902. He played a major role in the establishment of the Ballarat Y.M.C.A. and from 1906 responsible for evening classes in physical culture. In 1968, aged 91, he was made a Life Member of the Association. Steane was in complete command of his school, his staff and students. It must be remembered that schooling was not as permissive, tolerant and informal as today. A.W. Steane retired in 1942 after 29 years as Headmaster of Ballarat Junior Technical School. Many visible memorials are evident of his time and influence on the growth of the Junior Tech. A good school also lives on in the memories and affections of its old boys. Many remained in touch to talk about "the old days". A simple lesson he taught was "Win Through". No matter what path was chosen by the students, many were true to his teaching. On his retirement, Mr Jeffery was appointed the new Headmaster. On 19 March 1942, a farewell meeting was held presided over by Mr Jeffery. Those present included A.F. Heseltine, G. Netherway (representing the Old Boys' Association), N. McHuthchinson (District Schools' Inspector), G.A. Simcock (High School), E. Youlden (Pleasant Street State School), and J.A. Ewins (Citizens' Representative). The following presentations were made: G Netherway - nickel-plated smokers' stand with the Old Boys' badge A. Robinson - an illuminated scroll (B&W photograph above) C. Jeffery - lounge room clock with inscribed silver plate Steane died, aged 93 years, on 13 July 1970, at Sydney, leaving his widow Grace Elliott Steane and children Eric and Violet. Black and white image of an illumination for the retirement of Albert W. Steane. Written in calligraphy and signed by the President and Secretary of the Old Boys' Association. Dated March 19th 1942 .1) Framed colour illumination with ribbons in School coloursSignatures of H. Daykin, President and Alan Robinson, Secretary of the Ballarat Junior Technical School Old Boys' Association. Dated March 19th 1942.albert steane, sandhurst, bendigo, gravel hill state school, teacher monitor system, teaching certificate, sloyd, ballarat sloyd centre, gymnastics, y.m.c.a., ballarat junior technical school, n. mchutchison, a heseltine, george netherway, c jeffery, old boys' association, illuminated scroll, h. daykin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Kiwi Shoe Polish Manufacture, 1940s

The polish was developed in Australia by William Ramsay who named it Kiwi after the flightless bird endemic to New Zealand, the home country of his wife, Annie Elizabeth Meek Ramsay. Its success in Australia expanded overseas when it was adopted by both the British and American armies in World War I. In the UK, Kiwi was for many years manufactured at its British headquarters in Ealing (Brumwell Road, London W5 1DT). From here the factory manufactured for the UK market and exported the Kiwi brand too much of Europe and the Middle East. In the mid-1970s, as part of a major streamlining, the UK factory was closed with production switched to France. The UK operation moved to Surrey at Yately becoming, effectively, a sales and marketing office, with distribution contracted to a third party. In 1980, production for the UK market moved back to the UK and was housed in a factory near Huddersfield. The UK head office was relocated to Maidstone, Kent, where Kiwi had other product interests. Following the global merger with Nicholas Laboratories, the UK head office was again relocated to Slough at the Nicholas building on Bath Road.A significant product as Kiwi is an Australian brand name of shoe polish, first launched and sold in Australia in 1906 and as of 2005 sold in almost 180 countries. Previously owned by the Sara Lee Corporation since 1984, it was sold in 2011 to S. C. Johnson. It is the dominant shoe polish in some countries, including the United Kingdom and the United States, where it has about two thirds of the market. In Malaysia and Singapore, Kiwi has become such a household brand for a shoe polish that the word "kiwi" has been genericized into a verb in the Malay language, meaning "to polish one's shoes".Metal cleaning outfit of Kiwi boot polish brush, scraper, & polish missingKiwi Boot Polish to front of containerflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Carronade, Unknown (Replica)

This deck cannon is believed to be a replica Carronade as it has no foundry mark, year of manufacture, proof marks or weight of carronade on it. However, its design matches the design of Carronades used in the early to mid 19th century. History: The carronade was designed as a short-range naval weapon with a low muzzle velocity for merchant ships, but it also found a niche role on warships. It was produced by the Carron iron works and was at first sold as a complete system with the gun, mounting, and shot altogether. Carronades initially became popular on British merchant ships during the American Revolutionary War. A lightweight gun that needed only a small gun crew and was devastating at short range was well suited to defending merchant ships against French and American privateers. Its invention is variously attributed to Lieutenant General Robert Melville in 1759, or to Charles Gascoigne, manager of the Carron Company from 1769 to 1779. In its early years, the weapon was sometimes called a "mellvinade" or a "gasconade". The carronade can be seen as the culmination of a development of naval guns reducing the barrel length and thereby the gunpowder charge. The Carron Company was already selling a "new light-constructed" gun, two-thirds of the weight of the standard naval gun and charged with one-sixth of the weight of the ball in powder before it introduced the carronade, which further halved the gunpowder charge. The theory of its design was to use less powder and had other advantages that were advertised in the company's sales pamphlet of the time, state. The smaller gunpowder charge reduced the barrel heating in action, also reduced the recoil. The mounting, attached to the side of the ship on a pivot, took the recoil on a slider, without altering the alignment of the gun. The pamphlet advocated the use of woolen cartridges, which eliminated the need for wadding and worming, although they were more expensive. Carronades also simplified gunnery for comparatively untrained merchant seamen in both aiming and reloading that was part of the rationale for adopting the gun. Other advantages promoted by the company were. The replacement of trunnions by a bolt underneath, to connect the gun to the mounting, reduced the width of the carriage that enhanced the wide angle of fire. A merchant ship would almost always be running away from an enemy, so a wide-angle of fire was much more important than on a warship. A carronade weighed a quarter as much as a standard cannon and used a quarter to a third of the gunpowder charge. This reduced charge allowed Carronades to have a shorter length and much lighter weight than long guns. Increasing the size of the bore and ball reduces the required length of the barrel. The force acting on the ball is proportional to the square of the diameter, while the mass of the ball rises by the cube, so acceleration is slower; thus, the barrel can be shorter and therefore lighter. Long guns were also much heavier than Carronades because they were over-specified to be capable of being double-shotted,(to load cannons with twice the shot, for increased damage at the expense of range). Whereas it was dangerous to do this in a carronade. A ship could carry more carronades, or carronades of a larger caliber, than long guns, and carronades could be mounted on the upper decks, where heavy long guns could cause the ship to be top-heavy and unstable. Carronades also required a smaller gun crew, which was very important for merchant ships, and they were faster to reload. Additional notes: Cannon cast in England, Wales and Scotland had their imperial weight chiselled or engraved in the format of 4-2-0 on the bottom of the cascabel, indicating the weight of the cannon as 4 hundredweight, 2 quarters and 0 pounds. Since a hundredweight equals 112 pounds and a quarter weight is 28 pounds the total weight is 504 pounds or about 228 kilograms. The small bore replica carronade and carriage is part of a collection of nineteenth Century Flagstaff Hill Guns and cannons, and is a representation of carronades used from the early 18th up to the 1850s on merchant and military ships particularly the British Royal Navy until 1850. This example is not significant in the historic sense but demonstrates the type of artillery used aboard vessels of the time for protection & offensive military actions. Cannon, cast iron, small smooth bore cannon on the stepped wooden carriage with wooden wheels. It appears to fire a 12-pound cannonball. The Cannon barrel can have its elevation adjusted via a sliding sloped block at the rear of the cannon. Gun carriage has loops for locating and holding the carriage in position with the use of ropes. It is believed this carronade is a replica of a mid-to-late 19th-century Carronade cannon.Cast into metal; [Royal emblem of Queen Victoria (VR "Victoria Regina")]warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannon, naval cannon, cannon on carriage, 19th century cannon, fortifications, smooth bore cannon, 12 pounder, carronade, artillery, replica, deck cannon, cannon in carriage, ship cannon -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing or Jack Plane, Alexander Mathieson, Late 19th to early 20th century

In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medalThe firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Jack or Smoothing Plane Size of iron 2 1/4 inches wide.Has GN inside a W stamped for (A Mathieson & Son Glassgow.)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jack plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fillister Wood Plane, A Mathieson and Son, Mid to late 19th Century

The British wooden sash fillister plane is an old plane designed for rebate or rabbet work on sash windows to cut a groove or channel to allow a window to move up and down. The function and design of the sash fillister plane is a cross between the wooden moving fillister plane and the wooden plough plane. The wooden sash fillister plane is equipped with a fence, depth stop, nicker, skewed cutter and wedge. The plane has a hardwood main body, a hardwood moving fence and usually a variety of brass decorative and functional parts. The body and fence are nearly always made from beech as this was the hardwood of choice at the time these plane were made due to price and availability. Sometimes these planes are seen in other types of wood with the best examples being made from boxwood, rosewood and also there are some ebony fillister planes. Manufacturer: In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medalThe firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Sash Fillister Plane, with iron set skewed, the iron is 1 3/4 inches wide. Plane has a sliding adjusting fence, thumb screw depth stop and two knocking iron . Stamped W. Worrall, (owner) No 17. Maker A Mathieson & Sonflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, fillister sash plane, window making tool, carpenders tools, alex mathieson & sons, sash windows -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Book, New Century Press Pty.Ltd, Bid Time Return, 1977

The author tells of her life from the age of two (1889) living in Cheltenham Victoria her years at Cheltenham State School, Teachers Training College, teaching in Melbourne and the country and up till 1920 when she got married and left teaching for awhile she returned to teaching and became Victoria's first full time teacher-librarian at the Presbyterian Ladies' College she was a pioneer in teaching school library practice and visual education.168p., 8p. of plates ; A small soft cover book white with a coloured photograph of the author, the title and the authors name in red on the front cover,on the back cover is text by the author and a sepia photograph of an unknown early city.non-fictionThe author tells of her life from the age of two (1889) living in Cheltenham Victoria her years at Cheltenham State School, Teachers Training College, teaching in Melbourne and the country and up till 1920 when she got married and left teaching for awhile she returned to teaching and became Victoria's first full time teacher-librarian at the Presbyterian Ladies' College she was a pioneer in teaching school library practice and visual education. cheltenham, mentone, victoria, steam train, dog boxes, cheltenham state school, presbyterian ladies college, library. school teacher. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph - Back to Cheltenham State School - A memento 28.11.1936, 1936

A reunion gathering for past students of Cheltenham State School held in November 1936A black and white photograph of a large group of men and women in a semicircle on a school play yard beside a weatherboard building .They all appear to be smartly dressed, many women wearing hats and the men in suits. Cheltenham School Reunion. The third annual "Back to Cheltenham State school" reunion attracted an attendance of 600 former scholars to the school on Saturday afternoon. The proceedings were opened by tho mayor of Moorabbin (Cr. J. W. Allnut). The oldest teacher present was Mrs. Grant, of Sorrento, who, as Miss Fraser, had charge of the school from 1880 to 1883. Another old identity was Mr. T. Evans, of Kew, who is 82 years of age — he was the head teacher from 1802 to 1800. Photographs were taken of Mrs. Grant with fifteen of her former pupils, and of Mr. Evans, who mustered 72 of his old scholars. The roll call showed that there were 50 pupils present who attended tho school more than half a century ago. Mrs. Buckley, of Mentone, who is 84, and Mr. W. P. Fairlam, of Cheltenham, 80 years, were the oldest former scholars in attendance. Mr. Fairlam, notwithstanding his age, still carries on the business of an auctioneer. Bouquets were presented to Mrs. Grant and Mrs Buckley by the president of the mothers' club (Mrs. Marshall). An enjoyable day was wound up by a dance at night in the mechanical institute, when 200 attended. (Age, Monday 30 November 1936, page 5)cheltenham primary school, state school, charman road, cheltenham, school, charman stephen, gettens mary, spring grove, balcombe road, nepean road, dairy farmers, market agrdeners, poultry farmers, methodist church, cancel, 1936 -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

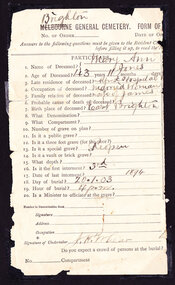

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Certificate - Documents relating to Death and Burial of Mary Ann Jones, 1903

James Jones was the son of Philip Jones, a Chairmaker, and Ann Jones who settled in East Brighton after the sale of land c1852 in the area of the Henry Dendy Special Survey of 1841. Mary Ann Moore was the daughter of Thomas Moore, a Gardener, and Sarah Harris who also settled in Brighton c1852. James and Mary Ann Jones settled and raised their family in East Brighton now Bentleigh. Mr John Herron resided at 4 Vickery St Bentleigh until 1989. Sadly Martha Jones born 1888 died in 1890 and James Jones had to purchase a plot at Brighton General Cemetery for her burial. Baby Ethel May was interred in 1893 and then Mary Ann in 1903 and James in 1940. Their stillborn baby was buried in the Wesleyan public grave in 1900James Jones and Mary Ann Moore were born in Brighton c1857 and c 1859 into pioneer market gardener families in the area of the Dendy Special Survey of 1841. They married in 1883 and raised their family in East Brighton, now Bentleigh. Sadly infectious diseases took the lives of many infants throughout the Colony of Victoria due to the poor state of water supply and sewerage disposal and locally the swamps of the Elster Creek were a constant breeding ground. Martha Jones born 1888 died 1890 and was interred in Brighton General Cemetery in a family plot purchased by her father James Jones. In 1893 another daughter Ethel May died and was buried in the family plot. A stillborn baby was interred in the public grave of Brighton General Cemetery in May1900. Mary Ann Jones died at age 43years and was interred in January 19033 Original documents associated with the death of Mary Ann Jones 18th January 1903. 1) An original paper receipt No. 4797 for payment on 19th January 1903 by James Jones to Brighton General Cemetery of £1 . 1s for the burial of Mary Ann Jones in a plot 4 feet x 8 feet, in the Wesleyan section portion 199 compartment G. 2 ) An original part- section of Form of Notification of Death from The Alfred Hospital Prahran with personal particulars and burial details , signed by the Undertaker. 3) An original Mourning Card 1) BRIGHTON GENERAL CEMETERY / 4797 ( stamped) / 19th Jan. 1903 (hand written) / Received from “Mr James Jones”(hand written) / the sum of £1 . 1s being the following / charges in Wesleyan (hand written) / Portion No, 199 compt.G Name of / Deceased ‘Mary Ann Jones”(hand written) / For re-opening grave interment ‘third’ £1 . 1s./ signed by S. P. Simmonds Secretary. 2) ‘Brighton’ (written over Melbourne) GENERAL CEMETERY FORM OF… / No. of Order____ Date of… / PARTICULARS / Signature of Undertaker J H Lear On back of notice are guides to the questions 3) In Loving Remembrance of / Mary Ann Jones / Dearly Loved Wife of James Jones / Died January 18th 1903 / Aged 43 Years / Poem - “One Less at Home “ / DEEPLY REGRETTED / Art Engraving Company, Royal Arcade, Elizabeth Street, Melbourne * wesleyan church, brighton general cemetery, vaccination, pioneers, early settlers, typhoid, brighton, moorabbin, bentleigh, market gardeners, jones james, jones mary ann, jones martha, dendy henry, dendys special survey 1841, infectious diseases, water supply, elster creek, melbourne, orford g h, printers, southern cross office, “brighton leader” print, bay street brighton, jones ethel may, public grave brighton -

Bendigo Historical Society Inc.

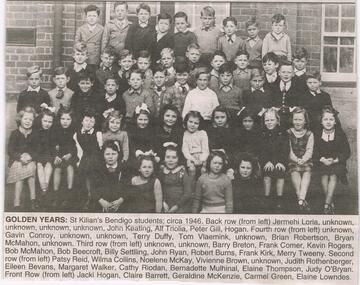

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: GOLDEN YEARS

Bendigo Advertiser '' the way we were'' from 2002. Golden years: st Killian's Bendigo students; circa 1946. Back row (from left): Jermehi Loria, unknown, unknown, unknown, unknown, John Keating, Alf Triolia, Peter Gill, Hogan. Fourth row (from left): unknown, Gavin Conroy, unknown, unknown, Terry Duffy, Tom Vlaemink, unknown, Brian Robertson, Bryan McMahon, unknown. Third row (from left): unknown, unknown, Barry Breton, Frank Comer, Kevin Rogers, Bob McMahon, Bob Beecroft, Billy Settling, John Ryan, Robert Burns, Frank Kirk, Merry Tweeny. Second row (from left): Patsy Reid, Wilma Collins, Noelene McKay, Vivienne Brown, unknown, Judith Rothenberger, Eileen Bevans, Margaret Walker, Cathy Riodan, Bernadette Mulhinal, Elaine Thompson, Judy O'Bryan. Front row (from left): Jacki Hogan, Claire Barrett, Geraldine McKenzie, Carmel Green, Elaine Lowndes. The clip is in a folder.newspaper, bendigo advertiser, the way we were -

Bendigo Historical Society Inc.

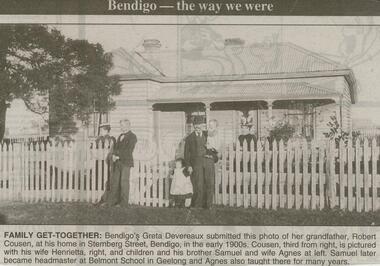

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: FAMILY GET TOGETHER

Bendigo Advertiser ''The way we were'' from 2000. Family get-together: Bendigo's Greta Devereaux submitted this photo of her grandfather, Robert Cousen at his home in Stenberg Street in the early 1900s. Cousen, third from right, is pictured with his wife Henrietta, right, and children and his brother Samuel and wife Agnes at left. Samuel later became headmaster at Belmont School in Geelong and Agnes also taught there for many years. The clip is in a folder.newspaper, bendigo advertiser, the way we were -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: VICTORIAN RAILWAYS CERTIFICATE