Showing 62 items matching "kitchen appliance"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPie Iron Camping, circa mid to late 1900s

This Pie Iron was used in the mid to late 1900's when stock, both cattle and sheep, were grazed on the Bogong High Plains. Providing meals for stockmen over open fires, even in log cabins in the Victorian Alpine region, was usually by a "camp cook" or a stockman designated "cook" from the Valley station/property. The use of "camping cooking utensils were a necessity and not a "weekend" affair. Stockmen could spend up to six weeks on the plains and all their cooking needs required had to "pack horsed" from the valley below. A scientific study started in 1947, to study the impact of grazing cattle on the natural Alpine and sub Alpine vegetation found grazing cattle had an adverse affect on the natural Alpine and sub alpine vegetation, and grazing on the plains was stopped by the Victorian Government in 2005.This item is highly significant to the Kiewa Valley as it demonstrates the kind of cooking utensils that were required for camp drafts in the Bogong High Plains environment. As the control of cattle and sheep in the High Plains was very demanding upon horse and rider, good "tucker" was a pre- requisite for a successful operation. As the time spent in this remote location was governed by the climatic condition maximum utilisation of the very good pastures in the High Plains was crucial to a successful and profitable season.This pie iron has two pie forms in horizontal configuration and both top and base rounded forms are connected at one end (Top) with pop rivet application. This application allows for the "opening" up of the two halves. The bodies are made from cast iron in a "cup" form and a metal rod and wooden handle extend to permit the opening of the two sides. The inner side of the "cups" are smooth which relates to pie requirements and not the jaffle/sandwich irons. A clasp metal "D" ring is installed at the end of one wooden handle (to keep the iron in the close/cooking position).camp fire cooking utensils, hot plate, cast iron cooking appliances, pie irons, jaffle irons, drovers kitchen -

Orbost & District Historical Society

Orbost & District Historical Societycheese mold

... gippsland This domestic kitchen appliance is typical of the period ...This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesVery rusted round tin with detachable bottom and lid for easy removal of cheese. Small eyelets on each side and large handles each side. Top and bottom lids have holes in them to allow moisture to escape.cheese-mould domestic food-preparation -

Orbost & District Historical Society

Orbost & District Historical Societyscales, 1930's

... . This item is an example of a common domestic kitchen appliance ...These cast iron scales were made for domestic use as they are quite basic and not accurate enough for commercial use.This item is an example of a common domestic kitchen appliance no longer in use.Large black kitchen scales with large dish that sits in metal claw.Underneath weights plates - 1lb 14ozscales instruments-weighing domestic kitchen -

Orbost & District Historical Society

Orbost & District Historical Societyraisin stoner, late 19th century

... gippsland This domestic kitchen appliance is typical of the period ...This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesA cast iron raisin stoner with a clamp. It has a wooden handle on a turning arm.On arm-PAT.APP. Aug 20.95 Oct 5-97 On one side- WET THE RAISINS On other side-ENTERPRISE M.F.C. PHILADELPHIA. P.A. U.S.A. On chute- No. 38raisin-stoner food-preparation -

Orbost & District Historical Society

Orbost & District Historical Societybiscuit forcer, mid 20th century

Biscuit dough was put into the forcer/case/cylinder and the wooden pin pressed down to force dough out as a shaped biscuit. This would have been used in use in an Orbost home in the mid 20th century.This item is representative of kitchen utensils in common use in working class kitchens in 20th century prior to the common availability of packaged biscuits.Biscuit paste forcer made up of a metal barrel with a ring for hanging at top and a wooden plunger with a knob handle on top. This is shaped like a rolling pin. Biscuit mix is forced through the end of the tube to create fancy-looking biscuits.domestic kitchen food-technology biscuit- forcer baking appliances -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, Kande Kitchenware, Circa 1924

Kande Kitchenware was established by Patrick Kavanagh and William English (the name Kande was formed from their initials, K and E) in 1922 and had its Sydney factory in Little Collins Street, Surrey Hills. Kavanagh and English, a subsidiary of Kande Kitchenware, became a limited company in 1924, with both founders as directors. Another director was Test cricketer Jack Gregory, an all-rounder who slipped easily into the role of businessman. Gregory enjoyed success in business as on the cricket field, helping the company grow from a tiny operation to a major manufacturer and exporter that employed 80 people in 1931. They managed to survive the Depression and kept manufacturing at least until the late 1960s.An appliance made by an early and successful Australian company that manufactured metal kitchen items during the first half of the 20th century. Colander enamel rusty holes in base of bowls, 2 handles, bowl shape.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, colander, kitchen item, domestic item, kitchen strainer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBiscuit Forcer

Dough was put in forcer/case/cylinder and wooden pin pressed down to force dough out as a star-shaped biscuit. In use in a working-class home in the mid 20th century.Representative of kitchen utensils in common use in working class kitchens in 20th century prior to the common availability of packaged biscuits. Tin/metal outer cylinder/case/open one end, lid other end, with star pattern (can be removed for washing). Inner wooden pin or forcer, knob on end to be pushed into metal cylinder to force dough out through patterned disc.domestic, kitchen, food, technology, biscuit, forcer, baking, woman s, work, appliances -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO PEOPLE

Date and Location Unknown - A Couple in a Gas Appliances Showroom Checking a Specials Catalogue in Front of a Gas Kitchen. On the Back Aulsebrook & Martin Pty Ltd Photographers 6 Ruth St. Golden Square 3555, Phone 054 437665.business, retail, gas and fuel showroom -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO PEOPLE

Date and Location Unknown - A Couple in a Gas Appliances Showroom Checking a Specials Catalogue in Front of a Gas Kitchen. On the Back Aulsebrook & Martin Pty Ltd Photographers 6 Ruth St. Golden Square 3555, Phone 054 437665.business, retail, gas and fuel showroom -

Robin Boyd Foundation

Robin Boyd FoundationFunctional object - Appliance

The Boyd family recalls this frying pan being used, but not sure of where it was located. The kitchen drawer where this frying pan is currently located was the toaster drawer. The drawer has a power point in it. "The drawer was pulled out and the drop down front lowered for toasting. When shut, no toaster was in sight! In the bottom of the drawer, at one side, there used to be a small slot for sweeping out any dropped bread crumbs."Electric frying pancookware, walsh st appliances, robin boyd -

Robin Boyd Foundation

Robin Boyd FoundationFunctional object - Appliance, "Semak" Vitamiser

The Boyds brought this vitamiser from their Camberwell home. Mandie Boyd, Robin and Patricia's eldest daughter, has very vivid memories of this gadget. "It made everything from milkshakes for us to mayonnaise, stuffing for chicken, soups, but especially I remember Robin in the kitchen using it to make daiquiris, endless ice, rum and lemon juice crushed and blended in the good old Vitamiser. He was wearing an amazing pale grey suit. American fabric beautifully cut, must have been synthetic, and had flecks of a darker grey through it, sounds hideous and was “of the time”. His American cotton business shirts were also beautifully tailored, with loads of room to move your arms unlike the daggy Aussie shirts." "Semak" Vitamiser, with a white plastic base, with 'on/off' switch at front of base. 4 black holders. Glass jug with black plastic lid. Black power cord. 3 black rubber stoppers at base.SN 7-81. 50 CYCLE 240v 120Wcookware, walsh st appliances, robin boyd -

Robin Boyd Foundation

Robin Boyd FoundationFunctional object - Appliance

The Boyd family think that this came from Robin Boyd's mother's house. Edith Susan Boyd, Robin’s mother, had a wonderful selection of earthenware crockery storage containers in her pantry, a huge walk-in room with open shelves off the kitchen. This scoop was needed to get any content out of these containers.Aluminium scoop (large) with handleThailand" "240 oz" on handle.cookware, gadget, walsh st kitchenware, robin boyd -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncCooker, circa 1960

... goldfields domestic items; kitchen appliances; food preparation ...Cream enamel, gas cooker with black painted, cast iron trivets. Gas gun attached. Enameled grill pan with grid.Brand name in black on front of oven door "New world".. Model name "Radiant" in black LLH corner of oven door.domestic items; kitchen appliances; food preparation; cooking -

Mont De Lancey

Mont De LanceyDomestic object - French Fry Cutter, Nutbrown Products

... appliances Kitchen tools Vegetable cutters Underneath the yellow ...Since 1932 Nutbrown has been producing crafted kitchen products which were a staple in British homes. Nutbrown continues to be in production today.A vintage manual metal and plastic Chipper and French Fry Cutter with two blue turned wooden handles each side which are attached to folding crossed metal supports joined to a square frame. The frame has 36 small squares with sharp blades on the edges to cut the potatoes A yellow coloured plastic support with raised squares under the cutter holds the potato in place. This is screwed to the metal base. There are pieces of cardboard from the original packaging explaining the use.Underneath the yellow support is stamped: ' A Nutbrown Product Patented Made in England Registered design'.domestic objects, kitchen appliances, kitchen tools, vegetable cutters -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Ceramic pie Funnel, Thomas M. Nutbrown, c1930

A ceramic pie funnel was a hollow ceramic tool that bakers and home cooks placed in the centre of pies to prevent the contents bubbling over. The hollow core allowed steam to escape during baking leaving the pie crust as light and flaky inside as on the surface. They came in a variety of shapes and sizes. This pie funnel was produced by Thomas M Nutbrown who started manufacturing kitchenware in 1927 from his factory on Walker Street, Blackpool. He registered the company in 1932 and over the following years his company was exporting goods all over the world. His company pioneered many unseen kitchen gadgets and utensils onto the market and had many products patented. The company closed in 1988.This item was typical of kitchenware used widely in the early twentieth century when a broader range of food items were home cooked.A ceramic pie funnel in the shape of an elephant. This is marked “NUTBROWN PIE FUNNEL Made in England” and was made by a company called Thomas M. Nutbrown Ltd of Blackpool. It also has a registered design number which is a little indistinct but is probably No 860928. It dates from the 1930’s and is in very good condition.On side of elephant in black ink "NUTBROWN/ PIE FUNNEL/ Made in England/ Reg. No 860928"domestic appliances, pie funnel, kitchenware early 20th century -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Dazey Churn, 1922

... produced more basic food items. Domestic appliances kitchen ...In the early 1900's, E.B. Jones developed a small glass churn for home use. Nathan Dazey purchased Jones' business and relocated it to St. Louis, Missouri as the Dazey Churn and Manufacturing Co. Dazey churns were manufactured up until 1945. Although best known for its butter churns, the company also made can openers, knife sharpeners and other kitchen products. Thes churns were widely used throughout households in rural Australia during the first half of the 20th century.This item was typical of kitchenware used widely in the early twentieth century when households produced more basic food items. A round glass churn with metal lid and mechanism. The handle was turned to rotate the paddle at the base of the mechanism in the jar. The jar holds 2 quarts of milk.The embossed Jar lettering is as follows: DAZEY CHURN No. 20 Patented February 12,1922 DAZEY CHURN & MFG. CO. ST. LOUIS, MO. MADE IN U.S.A.domestic appliances, kitchen appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Herb Cutter

... appliances Kitchen utensils A device with two sets of sharp metal ...This device was improvised to prepare herbs for cooking, It could chop bundles of herbs efficiently whilst also ensuring the users fingers were kept clear of the blades. The user held onto the handle and rolled the blades across the herbs to be cut. This item has typical of kitchenware improvised to complete tasks when more food preparation was completed in the home.A device with two sets of sharp metal rollers attached to a metal frame with a handle, The wooden handle is painted in green. domestic appliances, kitchen utensils -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Codling Collection 01 - Wodonga Fire station and CWA Hall

Miss Olive Codling was a Foundation Member and a Life Member of the Wodonga Historical Society. Many of her prize-winning photos are held in the Society Collection, including a series of photos of buildings in High Street (formerly Sydney Road), Wodonga. The CWA Hall officially opened in 1938 having been built on land granted by the Wodonga Council. Wodonga Infant Welfare Centre also occupied part of the building until 1959. Last meeting of the CWA in that hall was in held in December 1983, with the Council resuming ownership of the land to build the current day Post Office. Country Fire Brigade’s new fire station opened in High Street on 31st March 1940. The building comprised an appliance room for housing the fire engine and plant. The floor had been especially treated to enable dancing when the occasion warranted. There was a meeting room, a station-keeper’s bedroom and a repair shop. A shower room and modern kitchen were also included. The Fire station relocated to Smythe and Stanley Street corner which opened in 1977. They have now relocated to Thomas Mitchell Drive, Wodonga.This photo collection is significant as it documents how the businesses and buildings in Wodonga have evolved and contributed to community throughout the 20th century.A series of black and white photos depicting the Fire Station and CWA hall located in High Street, Wodonga C1940 - 1983wodonga businesses, high st wodonga, wodonga fire brigade, wodonga country women's association, cwa wodonga -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Meat mincer / Food chopper

... Australia Food chopper kitchen appliances Food preparation On Side 1 ...The Universal Food Chopper was a common domestic item internationally and throughout Australia. It was manufactured by the Landers, Frary & Clark company ( L.F. &C.). It was first sold in 1897, and proved to be so popular that the company still featured it in their catalogue sixty years later. It was marketed as a device that not only ground meat, but also processed vegetables. The number 2 on the device referred to the size of the grinder, with the 3 model being the largest for heavy-duty use and the 00 model the smallest. This appliance was a common domestic item used throughout AustraliaA cast iron and wood domestic appliance. The food chopper has a large screw on the base which allowed it to be anchored to a table or work bench. Food items were placed in the the cavity at the top and the user wound the handle to force the food through the blade. Different attachments allowed adjustments to the size the food was chopped.On Side 1: Pat. Oct.12, 1897/ Apr. 18, 1899/ Re Sept. 5, 1899 On Side 2 : LF & Co. /New Britain / CONN USA / No 2/ UNIVERSAL FOOD CHOPPERfood chopper, kitchen appliances, food preparation -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Food vitamiser, Semak, c1950

... Australian-made kitchen appliance used across the country. kitchen ...Semak is an Australian company, manufacturing Australian-Made equipment for the Foodservice Industry. It was established in 1948. The most famous Semak appliance is the 'Vitamizer'. Designed in 1948 it quickly became the standard for blending. An updated version was relaunched in 2012. The Semak vitamiser was advertised as a wonder machine which every housewife should have.Advertising claimed that the Semak could whip cream, grind coffee, blend jam, makes soups and sauces, makes cakes, sandwich spreads, ice-cream, special diets, puree fruit drinks, supper snacks, mayonnaise and dessert. It sold for £21. Demonstrations were conducted in electrical stores across the nation. A recipe book and full instructions for operation was included.This item is representative of a popular Australian-made kitchen appliance used across the country. A food vitamiser in 2 sections. Top section is detachable for cleaning. Has electrical cord attached.Surrounding power control: Semak Vitamiser Under base: CAT No. S2/ 230 - 25 V / 240W / 40 - 60kitchen appliances, food vitamisers, semak industries -

Wodonga & District Historical Society Inc

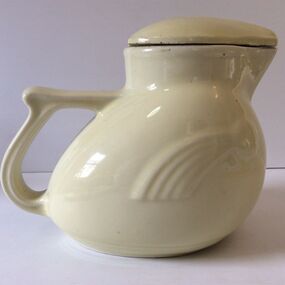

Wodonga & District Historical Society IncDomestic object - Ceramic KOOKABURRA Electric Jug, Nilsen Porcelain Australia, 1930s

... electric kettles kitchen appliances Nilsen Australia Earthernware ...Electric kettles were invented by the English to speed up tea preparation. In Australia fancy ceramic electric jugs quickly became a status symbol. During the Great Depression era anyone who could offer you a cuppa from a beautiful Electric Kookaburra Jug was considered to be doing well. Made by Nilsen Porcelain Australia in the 193Os, these kettles were unique for their charming art deco bird shape. Nilsen Electric Kookaburra Jugs are now regarded as a classic Australian icon prized by collectors. Oliver John Nilsen was born in Collingwood, Victoria in 1894. In 1916 he began his own electrical business, Oliver J. Nilsen & Co. (later Oliver J. Nilsen (Australia) Ltd). Nilsen's manufactured goods included such diverse products as transformers, bearings, battery chargers, bells, buzzers and gongs, porcelain ware, fuses, insulators and neon signs. Nilsen Porcelain Australia was a smaller company within the Nilsen group. Nilsen still operates as an electro-technology company operating throughout AustraliaThis jug is an excellent example of art deco ceramic appliances of the 1930s to 1950s on both a local and national level. It is also representative of products developed by a major Australian manufacturer. Earthernware ceramic jug, moulded in art deco style to represent an Australian kookaburra.vintage electric kettles, kitchen appliances, nilsen australia -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Ceramic mixing bowls, 1900 - 1950

Mixing bowls of this design were a common item in Austrailan kitchens in the late 19th and early 20th centuries. At this time the majority of women worked at home looking after their family and producing home-cooked meals. This type of bowl was a common domestic appliance used daily in Australian homes.This item is typical of kitchen utensils used in Australian homes in the early 20th century. No clear provence determined3 ceramic round mixing bowls of various widths - 340 mm, 300 mm and 265 mm. Each bowl has a pouring lip and decorative scallop relief around body. There is no indication of makers mark or source of production.Nonemixing bowl, domestic appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Flour Sifter made by KANDE Australia, Kande Kitchenware Ltd, 1920 - 1960

Kande Kitchenware was established by Patrick Kavanagh and William English in 1922. The name Kande was formed from their initials, K and E. It had its Sydney factory in Little Collins Street, Surrey Hills. Kavanagh and English, a subsidiary of Kande Kitchenware, became a limited company in 1924, with both founders as directors. Another director was Test cricketer Jack Gregory, an all-rounder who slipped easily into the role of businessman. Gregory enjoyed success in business as on the cricket field, helping the company grow from a tiny operation to a major manufacturer and exporter that employed 80 people in 1931. They produced a wide range of utensils including cake tins, pastry cutters, pans and baking dishes. They managed to survive the difficulties of the Depression and were listed as a public company in 1949. Kande Kitchenware Ltd were taken over by Hackshalls Limited 6 July 1960.An appliance made by an early and successful Australian company which manufactured metal kitchen items during the first half of the 20th century. Th.ese utensils were widely used throughout AustraliaFlour sifter manufactured by KANDE Australia. The sifter / sieve is made of metal with a wire mesh and is decororated with images of other kitchen utensils and ingredients. It has a spring-loaded handle to which would be squeezed to operate the internal sifting mechanism.At botton of illustrations on one side "Kande AUSTRALIA"australian business, kande kitchenware, kitchen utensils, kitchenware early 20th century -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Hand made toasting fork, Mid 20th Century

This fork was made by a member of the Conway family of Wodonga. It was used for making toast over an open fire well before modern toasters become widely available. It demonstrates the ingenuity of early settlers and pioneers before the advent of modern appliances and services. This item demonstrates the ingenuity of earlier pioneers and settlers to adapt to their living conditions and improvise from their available resources and environment.A hand-made wire toasting fork. It has three prongs and the handle is twisted with a loop at the top for hanging. It is made from fencing wire.hand made utensils, kitchen ware, pioneer skills -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Property Binder, 1184 Main Road, Eltham

... energy or water rated. Appliances in the timber kitchen include... energy or water rated. Appliances in the timber kitchen include ...Newspaper article: A sustainable award, Diamond Valley Leader, 1 November2006, Architect and building Llewellyn Pritchard won resource Efficiency Housing Award, finalist in HIA Greensmart Building of the Year Award. House – Environmental Leader (Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p186) In 2006 environmental awareness was mushrooming in the community, which is reflected in the award-winning house at Main Road near Wattletree Road, Eltham. At first sight, the building appears a mix of a classic Eltham mud-brick house and an avant-garde building style. The crown of solar panels stretching along the width of the curved roof, indicates that this is no ordinary house. In fact it signals a new building trend of minimal impact on the environment. Yet it utilises the environment with high technical expertise to achieve comfort and cut running and maintenance costs. In recognition of this, its designer/builder, Conscious Homes, won the 2006 National HIA Greensmart Resource Efficiency Award. For Conscious Homes director, Llewellyn Pritchard, this house reflects a philosophy, strengthened by his connection with Aboriginal culture, through his foster siblings. Pritchard believes the sustainable way indigenous Australians lived and their spiritual connection with land, demonstrates how humanity is part of the ecology. His interest in environmental design stemmed from growing up in bushy Eltham Shire, with its mud-brick tradition. This was followed by studying Architecture at RMIT in the early 1980s, and learning about passive solar design. Pritchard says this house demonstrates that environmental sustainability is not about sacrifice, but about exceptional levels of occupant comfort, savings in running costs and modern fittings and appliances.1 The solar panels on the north roofs are intentionally obvious to make a statement about what the building is doing. But inside the systems are hidden and interactive with conventional services, such as the underground water tank. The house is water and energy self-sufficient and at 12 squares is much smaller than conventional houses, to minimise resources. Yet it accommodates his family of four with three bedrooms, a living/dining and kitchen area and a bathroom/laundry. Importantly the building is designed to last hundreds of years, by being able to be modified as the need arises, such as for commercial use. In this way the structure minimises its environmental impact. The solid double mud-brick walls (which are insulated) include steel beams and supporting frame, allowing the future removal or alteration of any section. The materials are local, recycled and of low toxicity where possible.2 Inside and out, the mud-brick is rendered and sealed with a combination of cement and sand and a mud-based coating in a soft golden hue increases its life. Inside, the golden-brown timber is plantation Mountain Ash and the concrete floors throughout – of local stone aggregate with a clear seal – have a natural looking random stone appearance. The house sustains a stable temperature of around 20 degrees, assisted by the concrete slab floor. The many large double-glazed windows and highlights (windows set high on walls) provide cross-flow ventilation. The north-facing living area maximises heating from the lower winter sun and is cooler in summer, because the sun is higher. Heating comes from a solar hydronic slab system. All appliances and fittings are high efficiency energy or water rated. Appliances in the timber kitchen include a gas stove and a dishwasher, using the building’s own power and water. French doors open from the living area to a deck, concealing the treatment system for all waste water. This is pumped through sub-soil drippers to the indigenous garden beds and no-dig vegetable patch. Below the carport is the 80,000-litre rainwater tank and at the back, the boiler room houses the solar boiler, water tank access, domestic water supply pump, filter gear and hydronic slab heating controls. The solar system is backed up with gas, which is needed to heat water only in winter. Gas used is less than one quarter of that for an average home with ducted heating. Excess power is fed back to the grid and the building uses about one quarter of the mains electricity of an average home. Other local builders have followed Pritchard’s lead in resource efficiency for minimal environmental impact.main road, eltham, businesses, llewellyn pritchard, hia greensmart building of the year award., efficiency housing award, conscious homes australia pty ltd -

National Vietnam Veterans Museum (NVVM)

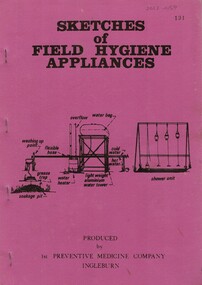

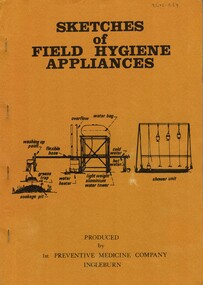

National Vietnam Veterans Museum (NVVM)Booklet, 1st Preventive Medicine Co, Sketches of Field Hygiene Appliances (Copy 2)

A pink coloured cardboard cover with black information on the front. There is the number 191 near the top right hand corner. Under the title of the booklet are several sketches. The booklet is held together with four metal staples down the left hand side.booklet, field hygiene, field kitchen, reticulated shower unit -

National Vietnam Veterans Museum (NVVM)

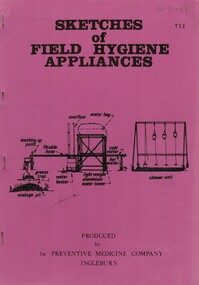

National Vietnam Veterans Museum (NVVM)Booklet, 1st Preventive Medicine Co, Sketches of Field Hygiene Appliances (Copy 1)

A pink coloured cardboard cover with black information on the front. There is the number 711 near the top right hand corner. Under the title of the booklet are several sketches. The booklet is held together with four metal staples down the left hand side.booklet, field hygiene, field kitchen, reticulated shower unit -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, 1st Preventive Medicine Co, Sketches of Field Hygiene Appliances (Copy 3)

A yellow coloured cardboard cover with black information on the front. Under the title of the booklet are several sketches. The booklet is held together with four metal staples down the left hand side.booklet, field hygiene, field kitchen, reticulated shower unit